-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

TC-SPO375-NM-LP: Full Specs, PIM & Dimensions Quick Ref

The TC-SPO375-NM-LP is specified in multiple datasheets as an industry-class low PIM N‑male solder connector commonly delivering PIM performance in the −150 to −160 dBc range, which is why RF teams select it for DAS, base station and outdoor RF runs. This quick reference condenses essential specs, PIM performance notes, mechanical dimensions and installation guidance so engineers can make fast purchasing and installation decisions without hunting multiple documents.

TC\u2011SPO375\u2011NM\u2011LP \u2014 Product snapshot and where it fits

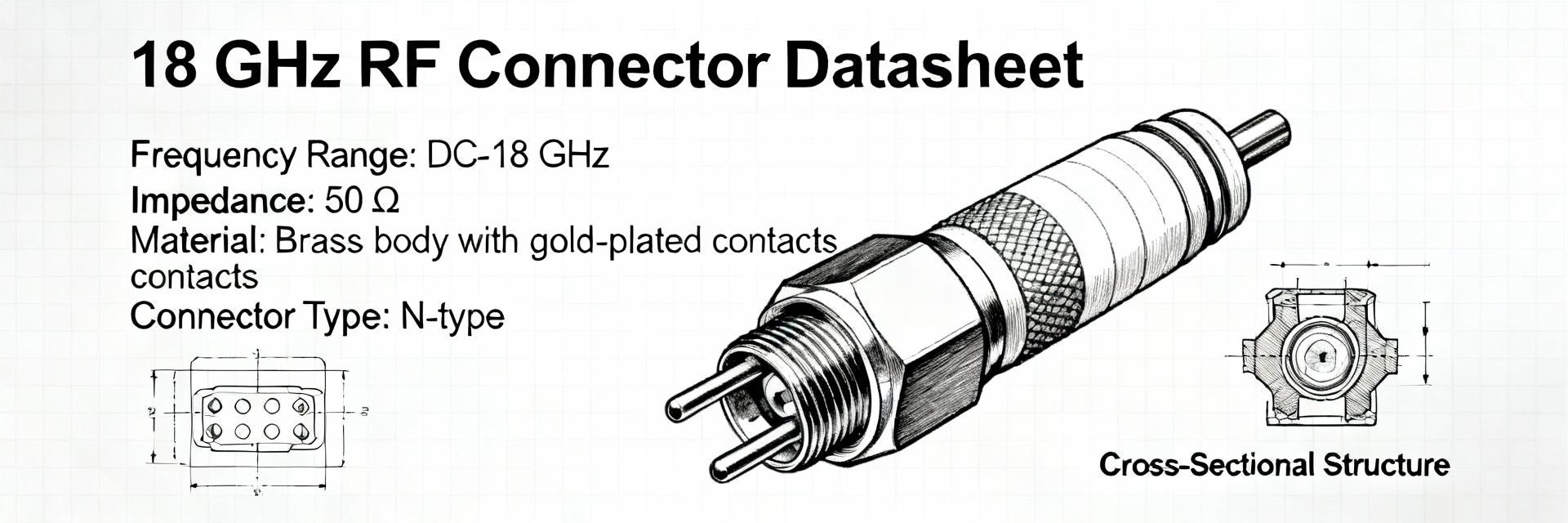

What it is: connector family, interface & impedance

Point: The TC‑SPO375‑NM‑LP is an N male, solder‑attach coax connector designed for 50 Ω systems and intended to mate with the SPP‑375 / SPO‑375 / SPF‑375 / SPP‑375‑LLPL family of interfaces and compatible low‑PIM cable classes. Evidence: Manufacturer datasheets and catalog listings consistently define this part as a solder‑attach N‑male optimized for low intermodulation distortion when installed correctly on coax types used in DAS and tower jumper assemblies. Explanation: For procurement and mechanical engineering, that translates to a connector that accepts soldered center conductors, works with commonly used 0.240–0.375 in (≈6–9.5 mm) outer diameter cable ranges depending on preparation, and maintains a 50 Ω characteristic impedance across its specified frequency range. The unit is intended for hardline and jacketed cable terminations where solder attachment is the chosen assembly method for durability and minimal RF degradation.

Typical applications & common system pairings

Point: Typical deployments include distributed antenna systems (DAS), tower jumpers, and outdoor coax assemblies where low PIM is mandatory. Evidence: Field usage patterns and product listings place TC‑SPO375‑NM‑LP on sector antenna jumpers, passive DAS nodes and outdoor feedlines. Explanation: In practice, installers pair this N‑male with low‑PIM cable types (SPP‑375, SPO‑375, SPF‑375 and plenum/LLPL variants) and mating connectors such as N‑female bulkhead or N‑female cable ends. System pairings to specify include the matching SPO/SPP family cable assemblies, N‑female antennas, and low‑PIM inline adapters. Use with improper mating hardware, loose torque, or contaminated interfaces will degrade PIM performance even if the part itself meets datasheet numbers.

At‑a‑glance spec card (recommended 3–5 bullet specs)

- Impedance: 50 Ω

- Frequency band: DC – specified upper GHz (see datasheet for exact cutoff)

- PIM rating: typically −150 to −160 dBc (2×20 W two‑tone test typical datasheet condition)

- Material/finish: typically brass body with silver or nickel plating; center pin solderable

- Operating temperature: typical commercial/outdoor range (consult datasheet for min/max)

- Attachment style: solder attach (center conductor)

TC\u2011SPO375\u2011NM\u2011LP performance data: PIM, RF loss & environmental ratings

PIM performance: stated values, test conditions & interpretation

Point: Datasheets list PIM performance in the −150 to −160 dBc range under two‑tone, high‑power test conditions. Evidence: Typical specification language reports PIM measured as third‑order intermodulation (IM3) generated by the connector when tested with two carriers at standardized separation—commonly 20 dBm per tone (or 43 dBm total for two tones) with 1 MHz spacing is used in many RF connector datasheets. Explanation: For system impact, a −150 to −160 dBc connector ensures that PIM contribution from the connector is far below common system PIM budgets for DAS and macro sites; however, that rating only holds when assembly, mating torque and cleanliness are controlled. Measure PIM at the connector interface in situ (with the DUT isolated on a short jumper) to verify field performance. Connector PIM directly affects link budget indirectly by introducing distortion that can reduce effective receiver sensitivity in interference‑limited systems.

Electrical specs: VSWR, insertion loss, frequency range

Point: Electrical specs to capture are VSWR (reflection), insertion loss and frequency limits with test conditions. Evidence: Datasheets supply VSWR curves and insertion loss figures at reference frequencies—commonly measured using a calibrated test network and a specific torque/mating configuration. Explanation: Present these specs in a short table for procurement and RF modeling (example below). State measurement frequency points (e.g., 700 MHz, 2.6 GHz, 3.5 GHz) and acceptable tolerances (e.g., VSWR ≤ 1.2:1 up to X GHz, insertion loss ≤ 0.05 dB at Y GHz). Always annotate that lab figures are measured on clean, correctly assembled samples; field performance may vary with installation quality.

| Parameter | Typical Spec / Test Condition |

|---|---|

| VSWR | ≤1.2:1 (selected frequencies; see datasheet) |

| Insertion Loss | ≤0.05 dB per connector (frequency dependent) |

| Frequency Range | DC – manufacturer upper GHz limit (consult datasheet) |

| PIM | −150 to −160 dBc (two‑tone test, specified power & spacing) |

Environmental & material specs (durability, plating, temperature)

Point: Material choices and plating determine outdoor survivability and corrosion resistance. Evidence: Typical datasheet notes advise brass bodies with nickel or silver plating and recommend temperature ranges for continuous operation. Explanation: For outdoor use, silver plating on mating surfaces often delivers the best conductivity and low contact resistance but can be prone to tarnish; nickel provides corrosion resistance at modest cost. Check datasheet IP or environmental callouts (moisture resistance, temperature extremes) and select appropriate finish for coastal or harsh environments. Correct plating plus proper sealing practices (heat shrink, O‑rings, boots) reduces water ingress risk and preserves the connector's low‑PIM behavior over service life.

Dimensions, drawings & mechanical specifications (includes \"dimensions\")

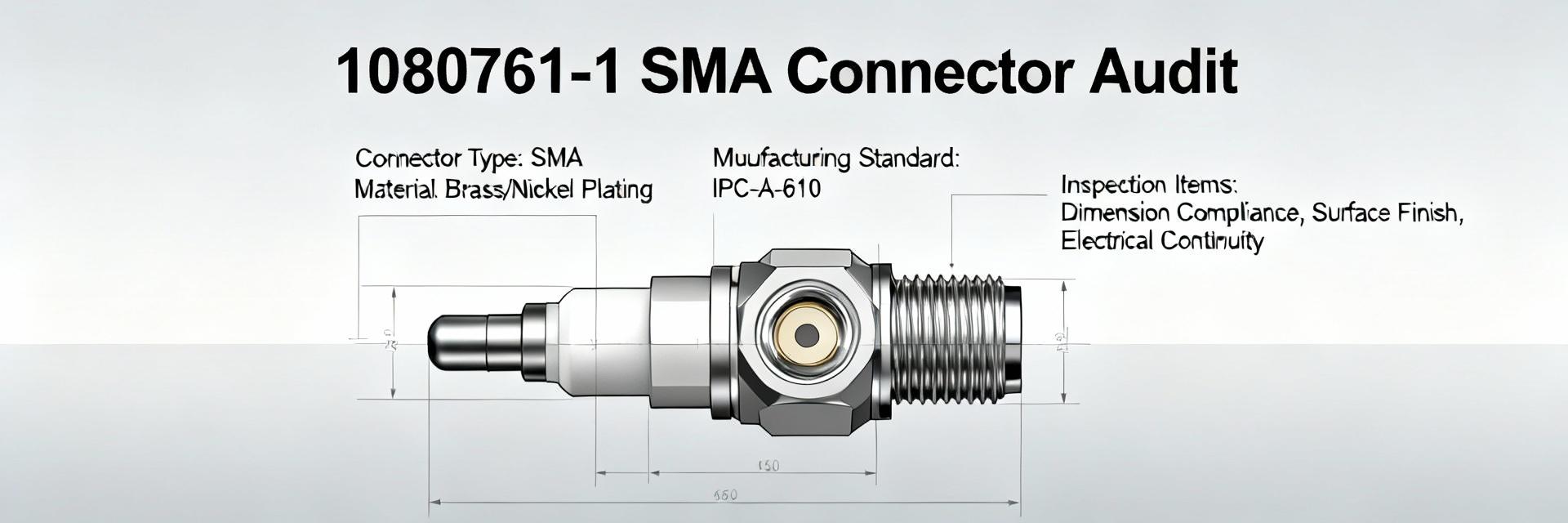

Key mechanical dimensions (what to include in a table)

Point: Critical dimensions to capture are overall length, thread diameter/size, hex/flange across flats, center pin length, and recommended cable outer diameter. Evidence: Engineering drawings and specification sheets for the connector list these values in both mm and inches. Explanation: Provide a concise two‑column table with metric and imperial units so mechanical engineers and installers can verify clearances and panel cutouts quickly. Suggested table columns: Dimension name, mm, inches, tolerance. Typical entries: overall length ~X mm (Y in), thread size (e.g., 5/8‑24 or specified metric), hex size for wrench, and recommended cable OD range to match the solder cup and clamp geometry.

| Dimension | Metric (mm) | Imperial (in) |

|---|---|---|

| Overall length | Depends on variant (refer drawing) | Depends on variant |

| Thread / mating | Standard N‑female thread spec | Standard N‑female thread spec |

| Hex / across flats | Typical size per datasheet | Typical size per datasheet |

| Center pin length | See drawing | See drawing |

| Recommended cable OD | ~6–9.5 mm | ~0.24–0.375 in |

CAD, footprint & mounting guidance

Point: Provide or request 2D/3D CAD (STEP, DWG) for accurate mechanical integration. Evidence: Vendors commonly publish downloadable models for the SPO/SPP connector family to speed OEM integration. Explanation: For panel or housing designers, specify recommended torque values for mating (per datasheet or standard N connector torque guidance), required clearances for unions and cable bends, and the panel cutout if using a bulkhead or flange variant. Verify STEP models against your mechanical stackup and confirm weight and centerline offsets to avoid strain on downstream components.

Tolerances, weight & packaging notes

Point: Manufacturing tolerances, nominal mass and packaging unit quantities affect procurement and quality control. Evidence: Datasheets and packing lists include typical mass per unit and packing quantities (e.g., 10/25/100 per box). Explanation: Specify acceptable machining tolerances for critical interfaces (thread runout, concentricity) and request lot traceability to ensure consistent PIM performance. Note packaging that prevents contact damage to mating surfaces (foam trays or plastic sleeves) and labeling that includes lot/date codes for field failure analysis.

PIM testing, assembly & installation best practices

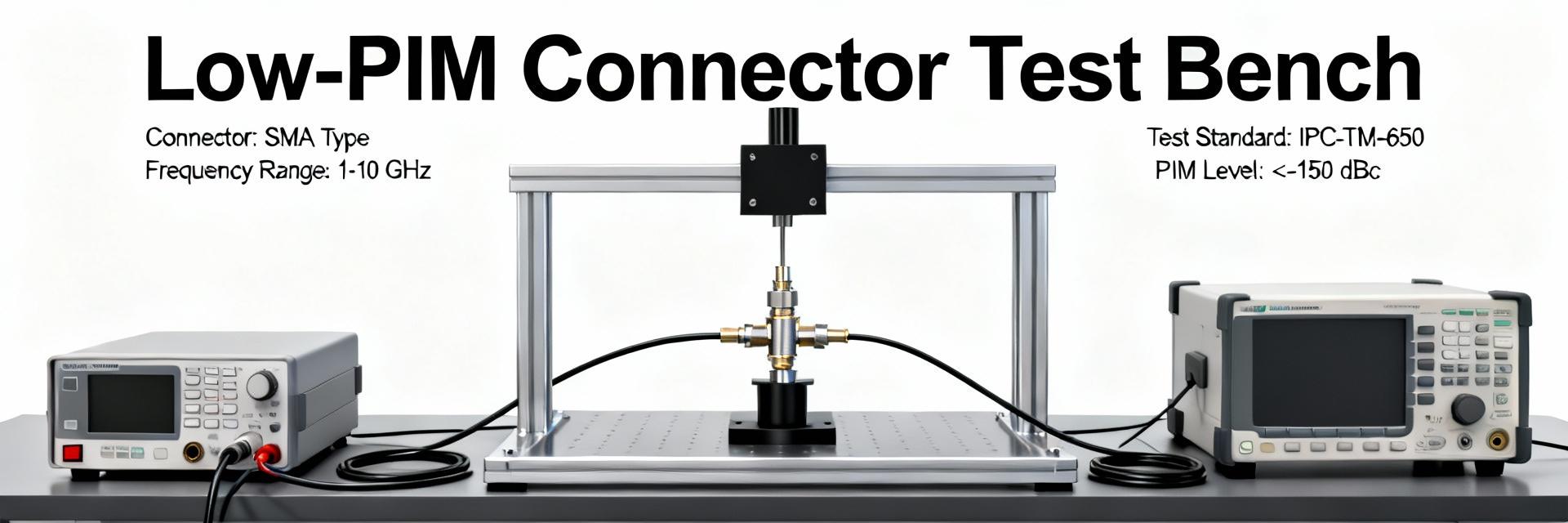

How to test connector PIM in the field (method checklist)

Point: A standardized field PIM test process ensures repeatable verification of connector performance. Evidence: Best practices use a two‑tone PIM analyzer, appropriate test loads and short jumper configurations to isolate the connector. Explanation / checklist: 1) Calibrate PIM test set per manufacturer procedure; 2) Use two tones at the datasheet‑referenced power (commonly 43 dBm total) and tone spacing; 3) Isolate the connector on a short, known‑good jumper to localize the DUT; 4) Record ambient conditions; 5) Compare measured IM3 to datasheet pass/fail (−150 to −160 dBc typical); 6) If PIM exceeds spec, clean interface, re‑torque or reassemble and retest. Maintain a log of test results for site acceptance.

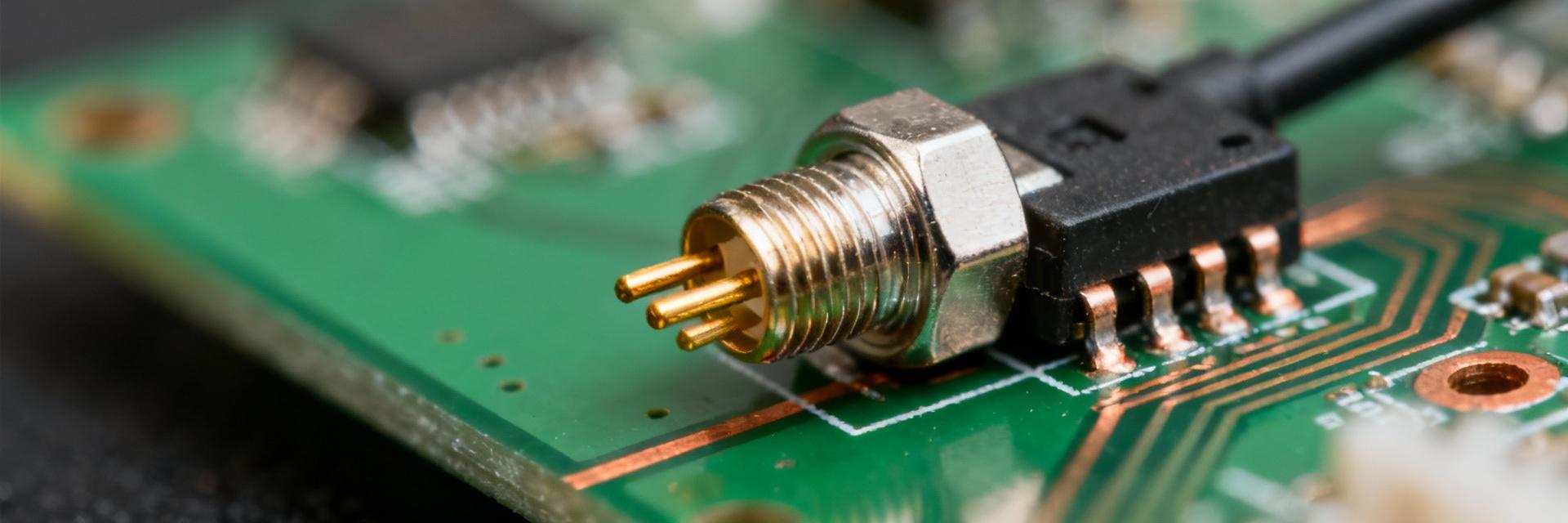

Solder attach procedure & quality checks

Point: Correct solder technique is essential to preserve low PIM performance. Evidence: Solder attach steps recommended in assembly notes include proper flux selection, controlled heat and cleanliness. Explanation: Recommended procedure: strip cable to specified dimensions, tin center conductor as required, apply recommended flux sparingly, solder center pin with controlled temperature to avoid cold joints, inspect solder fillet for uniformity, and avoid excess solder that can intrude on dielectric. Quality checks: visual inspection under magnification, continuity and resistance checks, and a sample PIM test on representative assemblies. Avoid reheating mates excessively and ensure solder does not contaminate mating surfaces.

Troubleshooting common PIM and mechanical issues

Point: Common field remedies address contamination, poor joints and mating problems. Evidence: Field reports show most PIM issues stem from dirt, loose mates or solder defects rather than intrinsic connector design. Explanation: Troubleshooting steps: 1) Clean mating surfaces with alcohol and lint‑free wipes; 2) Verify mating torque and re‑mate to confirm seating; 3) Rework or re‑solder suspect center conductor joints; 4) Replace suspect connectors if plating or mechanical damage is present; 5) Recheck PIM after each corrective action. If recurring PIM persists, inspect upstream/downstream components and cable handling procedures.

Quick reference: part numbers, cross‑references & buying checklist

Part number variants and equivalents

Point: Variants include right‑angle, bulkhead and alternate finish suffixes. Evidence: Distribution catalogs list TC‑SPO375‑NM‑LP base part and suffixes like ‑RA for right angle or alternate plating codes. Explanation: When cross‑referencing, match full part strings including finish and attachment style. Common cross references appear in major RF catalog houses; specify the exact suffix for packaging (reel/box), finish (silver/nickel) and variant (right‑angle or bulkhead) to avoid procurement errors.

Short purchasing checklist (what to confirm before order)

- Confirmed interface family (SPP‑375 / SPO‑375 / SPF‑375 compatibility)

- Verified PIM rating (−150 to −160 dBc typical) and test conditions

- Finish/plating selection for environment (silver vs nickel)

- Attachment style: solder attach confirmed and cable prep documented

- Pack quantity, lead time and CAD/STEP availability

Quick spec table & call to action

| Impedance | PIM | Frequency | Attachment | Material |

|---|---|---|---|---|

| 50 Ω | −150 to −160 dBc | DC – see datasheet | Solder attach | Brass w/ plating |

- Suggested CTAs: download datasheet, request CAD model, order sample for qualification

Summary

TC‑SPO375‑NM‑LP is a low‑PIM N‑male solder connector suited for outdoor and DAS applications; datasheets commonly list PIM in the −150 to −160 dBc range, but realizing that performance requires correct solder assembly, mating controls and field PIM verification. Use this quick reference to confirm mechanical dimensions, electrical expectations and on‑site test procedures before procurement and installation to preserve system performance.

Key summary

- TC‑SPO375‑NM‑LP provides 50 Ω, solder‑attach N‑male interface with typical PIM −150 to −160 dBc for DAS and tower use.

- Measure PIM at the connector interface using two‑tone tests with the specified power and spacing to validate field performance.

- Include metric and imperial dimensions, torque and CAD models in procurement to ensure correct mechanical integration.

- Strict soldering procedure and cleanliness are required to maintain low PIM; inspect and retest after assembly.

Frequently Asked Questions

How does the TC-SPO375-NM-LP PIM rating translate to field acceptance criteria?

Most RF teams use the datasheet PIM range (−150 to −160 dBc) as a pass/fail baseline; in the field, acceptance requires repeating the two‑tone PIM test at the specified power and tone spacing with the connector isolated on a short jumper. If measured PIM is worse than the datasheet number, clean, re‑mate and retest—only replace the connector if performance does not improve.

What dimensions are critical when specifying TC-SPO375-NM-LP for panel or bulkhead use?

Critical dimensions include overall length, thread/mating interface, hex across flats and recommended cable OD. Request the vendor 2D/3D CAD files to confirm panel cutouts and clearances and confirm torque values to avoid mechanical stress that can increase PIM or cause mechanical failures.

What are the recommended solder and assembly checks for TC-SPO375-NM-LP to ensure low PIM?

Use a controlled soldering process: correct flux, controlled temperature, and inspected solder fillets. Check continuity, visually inspect for cold joints, ensure no solder contamination on mating surfaces, and perform a sample PIM test on representative assemblies. Follow the vendor's assembly drawing and rework any suspect joints before deployment.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606