-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

Complete TE Connectivity 1051094-1 Datasheet & Specs

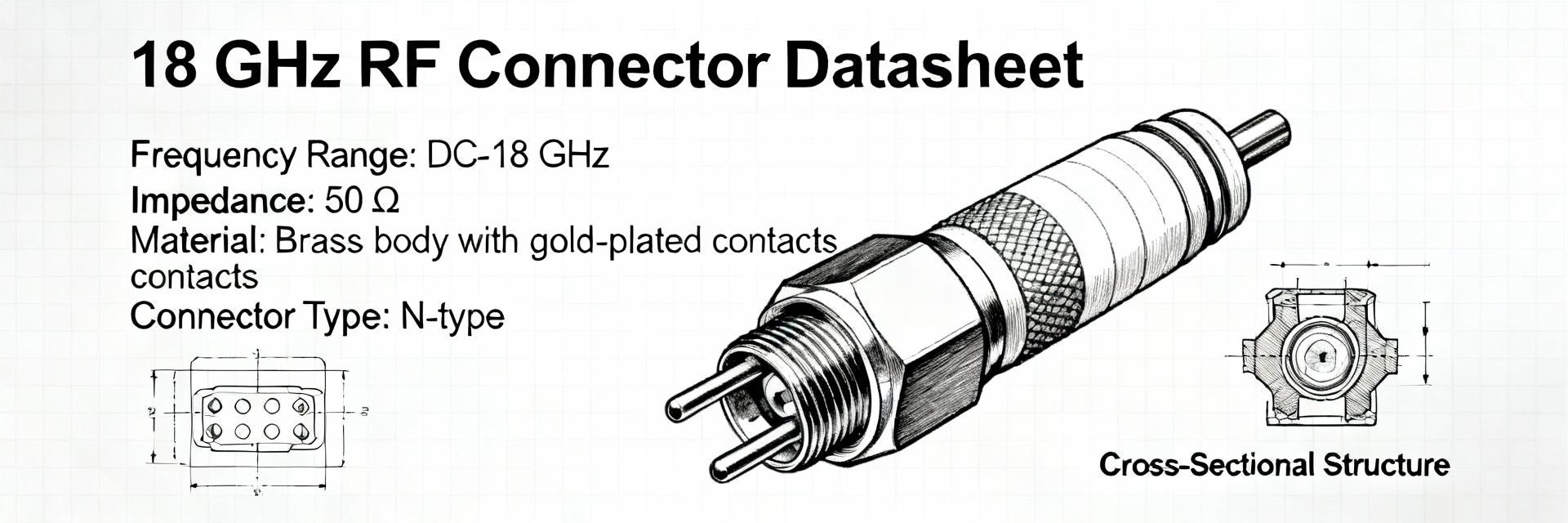

TE Connectivity 1051094-1 is an SMA-series RF jack rated up to 18 GHz — a key specification that determines suitability for high-frequency test, telecom and aerospace systems. This guide breaks down the full datasheet into engineer-usable sections: part identity and headline specs, electrical performance and power limits, mechanical drawings and materials, compliance and reliability data, typical applications and mating compatibility, plus practical procurement and substitution tips. Readers will get a concise checklist for extracting the critical numbers from the official datasheet and clear criteria for selecting or replacing this part in fielded systems.

TE Connectivity 1051094-1 — at-a-glance specs & part identity

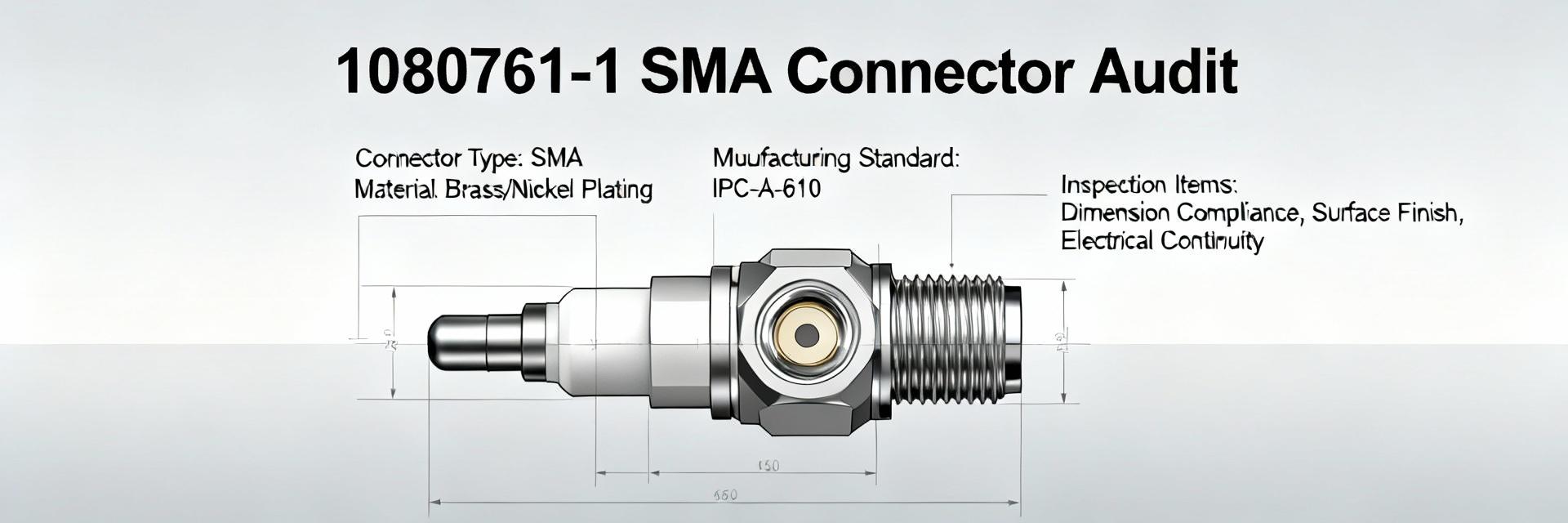

Part summary and part numbering

Point: 1051094-1 maps to TE’s cataloging convention where the base numeric code identifies the connector family and the dash suffix denotes a specific configuration or finish. Evidence: TE nomenclature typically pairs a family number with suffixes for plating, gender and mounting. Explanation: For this item you should expect manufacturer = TE Connectivity, series = SMA / RF, gender = jack (socket) format for panel or PCB mounting, and nominal impedance = 50 Ω. When ordering, confirm the full ordering code that may include additional digits for packaging, plating (e.g., gold or nickel), and quantity.

Headline electrical specs (quick table)

Point: Quick scanning table for design review. Evidence: Datasheet headline rows normally show max frequency, impedance, return loss/VSWR and rated voltage/current. Explanation: Use the following compact summary for early feasibility checks before diving into detailed plots and tables.

| Parameter | Value |

|---|---|

| Maximum frequency | 18 GHz |

| Impedance | 50 Ω |

| Typical VSWR / Return loss | VSWR ≤ 1.5 (typical band-dependent), return loss ≥ ~14 dB in passband |

| Contact resistance / Insulation | See electrical table in datasheet (mΩ / MΩ ranges) |

| Rated voltage/current | RF signal power ratings; DC ratings if provided on datasheet |

What the official datasheet provides

Point: A datasheet organizes all design-critical data. Evidence: Typical TE datasheets include sections for electrical, mechanical, materials, environmental and ordering. Explanation: Expect an electrical performance section (VSWR, insertion loss, frequency range), mechanical drawings with tolerances and mating information, materials and platings, environmental limits (temperature, vibration), qualification/test data (mating cycles, salt spray), and an ordering table showing full part numbers and packaging codes. Use the ordering table to ensure suffixes match desired finish and mounting style.

Electrical specifications — performance numbers and what they mean

Frequency range, impedance, and RF performance

Point: 50 Ω and a stated 18 GHz maximum define intended system roles. Evidence: The datasheet’s frequency axis and VSWR/return loss plots show how performance degrades with frequency. Explanation: A 50 Ω impedance means the connector is suited for standard coax RF systems; 18 GHz maximum indicates suitability for many microwave and lab-test applications but not for higher-mmWave bands. Read VSWR charts to determine passband windows: a VSWR of 1.2–1.5 is common at lower frequencies, rising near the upper limit. Return loss plots (in dB) reveal resonances—pick the connector only if insertion and return loss meet your system budget across the intended band.

Contact resistance, insulation resistance, and dielectric properties

Point: These metrics affect insertion loss, noise, and long-term reliability. Evidence: Datasheet tables list typical contact resistance (single-digit mΩ for center/outer contacts) and insulation resistance (often in the MΩ range). Explanation: Low contact resistance minimizes I^2R losses and thermal rise under DC bias; high insulation resistance and PTFE-like dielectrics reduce leakage and maintain dielectric constant stability. For RF, the dielectric constant and loss tangent of the insulator affect insertion loss and phase stability—verify material callouts and measured insertion loss figures for your frequency band.

Power handling and voltage ratings

Point: RF power and DC voltage limits are frequency- and cooling-dependent. Evidence: Datasheets typically provide power handling at different frequencies and note derating with temperature. Explanation: Power handling for SMA-class jacks at microwave frequencies is often in the single-digit to low-double-digit watt range (depending on VSWR and cooling); increases in VSWR or poor thermal paths reduce safe power. For DC or pulse voltages, use the specified voltage rating and apply conservative derating (50–75%) if operating near temperature limits or with extended continuous duty.

Mechanical & environmental specifications — dimensions, materials, and ruggedness

Mechanical dimensions and mating information

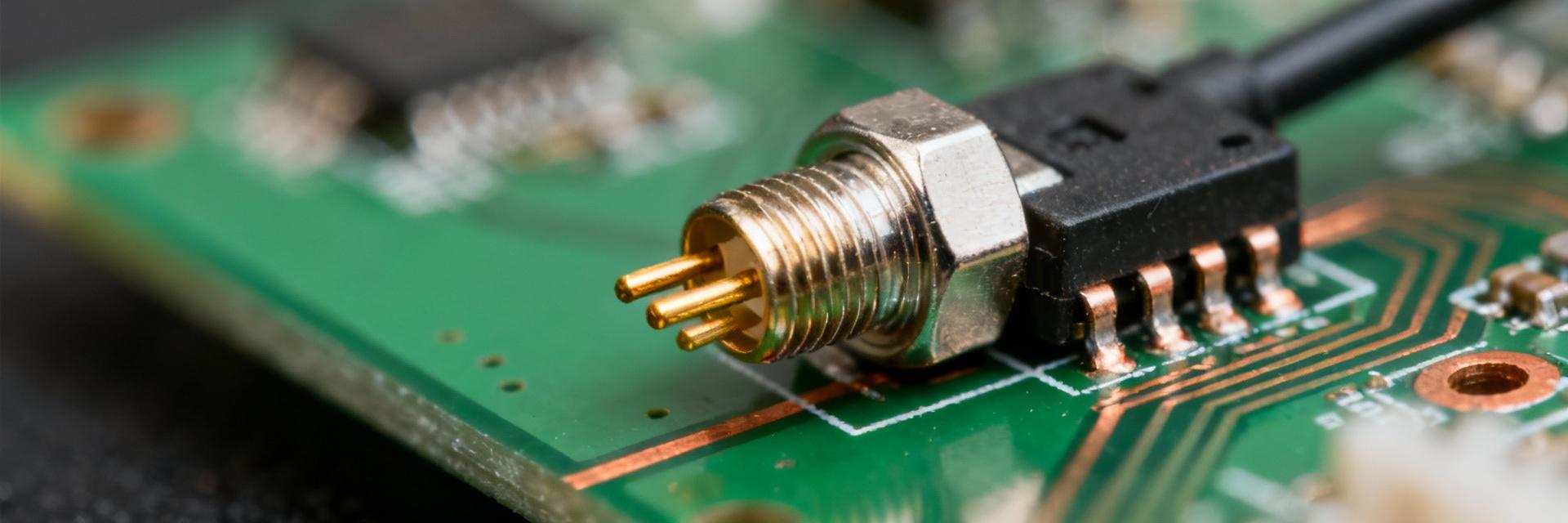

Point: Mechanical drawings are essential for mounting and mating compatibility. Evidence: The datasheet includes front and side views with critical dimensions (mating face, thread, flange holes, PCB footprint). Explanation: Verify the mating face dimensions and thread spec for proper engagement; check PCB footprint tolerances for through-hole or surface-mount variants. Note recommended mating torque for threaded interfaces and any specified mate/unmate procedures. Always pair the connector with a matching SMA plug or jack of the correct gender and mating face type to avoid RF degradation.

Materials, plating and contact finishes

Point: Body, contact, and insulator chemistry influence corrosion resistance and electrical stability. Evidence: Typical materials include brass or beryllium copper contacts and PTFE insulators; platings are nickel or gold over nickel. Explanation: Gold-plated contacts reduce contact resistance and resist fretting corrosion, while nickel bodies are mechanically robust but may show higher RF loss at high frequencies. For aerospace or long-term deployed systems, prefer gold-plated center contacts and specified corrosion-resistant finishes; check for any stated plating thickness and compatibility with soldering or wave reflow if PCB-mounted.

Environmental ratings: temperature, vibration, shock, sealing

Point: Environmental tables list operating/storage temperatures and mechanical qualifications. Evidence: Datasheet rows typically show operating range (e.g., −40 °C to +85 °C or wider), mating cycles, vibration/shock standards, and any IP or sealing notes. Explanation: Choose connectors whose rated temperature and cycle qualifications exceed your application stressors; for avionics or defense use, validate vibration and shock test levels against your system’s qualification plan. If environmental sealing is required, confirm whether the part is sealed or if an alternate sealed variant exists.

Compliance, testing & reliability data

Industry standards and certifications

Point: Compliance statements guide procurement and acceptance. Evidence: TE datasheets commonly list RoHS, REACH declarations and may reference industry standards (MIL, IEC) where applicable. Explanation: Confirm RoHS/REACH status for commercial electronics; for defense/aerospace, request explicit qualification against relevant MIL or industry standards. If the datasheet lacks a particular certification, contact TE or an authorized distributor for trace or qualification reports before acceptance testing.

Typical qualification and test results

Point: Qualification data (mating cycles, salt spray, thermal cycling) indicate expected durability. Evidence: Datasheets include test tables showing pass/fail criteria and measured values. Explanation: Interpret test results by comparing your application stressors: a mating cycle count (e.g., 500 or 1000 cycles) informs expected mechanical life; salt spray hours indicate corrosion resistance for coastal deployments; thermal cycling results show stability over temperature swings. Use these figures to build environmental margins in procurement specifications.

Traceability, lot coding and marking

Point: Lot codes and trace reports are critical for regulated procurement. Evidence: The ordering and packaging sections in datasheets document marking schemes and lot traceability options. Explanation: For high-reliability programs, request lot-by-lot certificates of conformity and test reports. Check the datasheet for shelf-life notes and storage recommendations; when authenticity is critical, purchase through TE-authorized distributors and retain trace documentation.

Typical applications, mating compatibility & performance in the field

Common applications by industry

Point: 18 GHz SMA jacks are used across test, telecom and aerospace. Evidence: Datasheet frequency and environmental specs align with bench instrumentation and airborne RF subassemblies. Explanation: Typical use-cases include lab test fixtures, RF test equipment, antenna feeds below mmWave, telecom equipment, and avionic RF harnesses. The 18 GHz limit covers many microwave links and certification test rigs where high-frequency performance without mmWave capability is acceptable.

Compatible mating connectors and cable assemblies

Point: Mating compatibility is governed by gender, thread and mating face. Evidence: Datasheet mating tables show compatible plugs and recommended assemblies. Explanation: Use matching SMA plugs rated for 50 Ω and the same mechanical style (e.g., precision vs. general-purpose). For cable assemblies, select RG-316 / RG-402 style coax or equivalent depending on flexibility and loss requirements; confirm assembly processes (crimp vs. solder) and torque values to avoid damage and maintain RF performance.

Real-world performance constraints and design tips

Point: Installation and maintenance impact long-term RF performance. Evidence: Datasheet notes on torque, mating cycles and contact finishes guide field practice. Explanation: Minimize insertion loss by keeping cable lengths short, maintaining proper torque on threaded connectors, and avoiding repeated unnecessary mate/demate cycles. For PCB-mounted variants, ensure appropriate ground vias and keep RF traces short with controlled impedance to prevent reflections. Plan for regular inspection and replacement schedules in harsh environments.

How to read the datasheet, order parts and find alternatives

Step-by-step: extracting the exact specs you need from the datasheet

Point: A checklist speeds validation. Evidence: Datasheets are structured to let engineers locate key tables quickly. Explanation: Start with the electrical table (frequency, VSWR, insertion loss), then mechanical drawing (dimensions, footprint), then materials/plating and environmental tables. Finally consult the ordering table for full part numbers and packaging. Use test graphs to validate performance across your operating band rather than relying solely on headline numbers.

Ordering, part variants, cross-references and authorized distributors

Point: Use full ordering codes and authorized channels. Evidence: The datasheet shows ordering codes; major distributors list SKUs. Explanation: Build the full ordering code to include plating, packaging and optional features. Purchase through TE-authorized distributors to ensure authenticity and get traceability documentation. When in doubt, request manufacturer confirmation of the ordered suffixes and view distributor product pages or stock records for lead times and minimum order quantities.

Alternatives and replacements

Point: Identify equivalents by matching impedance, frequency and mounting style. Evidence: Cross-reference tables or TE cross-part lists can indicate direct equivalents. Explanation: When seeking replacements, match these core attributes: 50 Ω impedance, ≥18 GHz rated frequency (or higher for margin), same gender and mounting type. Consider higher-rated TE parts or alternate manufacturers if you need wider bandwidth, sealing, or higher power handling—verify mechanical compatibility before substitution.

Summary

TE Connectivity 1051094-1 is an SMA-class 50 Ω jack rated to 18 GHz; key specs to confirm on the datasheet include max frequency, VSWR/return loss, contact and insulation resistances, material/plating, and environmental qualifications. For procurement, use the datasheet ordering table to construct the full part number, buy through authorized distributors, and request trace/test reports for critical programs. Next steps: download the official TE datasheet, verify the mechanical drawing against your footprint, and order samples for insertion loss and VSWR verification in your system.

Key summary

- Headline performance: 50 Ω SMA jack rated to 18 GHz—verify VSWR and insertion loss across your intended band before integration.

- Mechanical and materials: check the datasheet drawing for mounting tolerances and confirm plating (gold vs. nickel) based on corrosion and contact resistance needs.

- Reliability & compliance: use qualification tables (mating cycles, thermal/vibration) to match application stressors; request lot traceability for regulated programs.

- Procurement: construct the full ordering code from the datasheet, use authorized distributors, and obtain test/trace reports when required.

Common questions & answers

What are the critical specs to check on the TE Connectivity 1051094-1 datasheet?

Focus first on maximum frequency, VSWR/return loss, and insertion loss curves to ensure the part meets RF performance in your band. Next confirm impedance (50 Ω), contact and insulation resistance values, and any voltage/power ratings. Finally, verify mechanical drawings, plating/material details and environmental tables (temperature range, mating cycles) for mounting and longevity considerations.

How can I verify mating compatibility for the 1051094-1 part?

Use the mechanical drawing and the datasheet’s mating information to match thread type, mating face dimensions and gender. Select mating plugs specified for 50 Ω SMA interfaces and verify recommended torque. For cable assemblies, pick an assembly type whose conductor/outer dimensions and crimp/solder method align with the connector’s recommended terminations.

What procurement steps reduce risk when ordering TE Connectivity 1051094-1?

Order using the exact catalog code from the datasheet and purchase through TE-authorized distributors. Request certificates of conformity and lot trace reports for critical programs. If lead time is an issue, seek authorized cross-references or higher-spec TE parts and confirm mechanical compatibility before acceptance testing.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606