-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1051098-1 Datasheet Deep Dive: Key Specs & Metrics

Rated to 18 GHz, the 1051098-1 RF connector packs performance that matters for modern RF links — but raw frequency alone doesn't tell the whole story. This article analyzes the datasheet to help engineers translate spec tables into system decisions: electrical performance, mechanical limits, environmental qualifications, measurement practices, and procurement guidance. It focuses on the most impactful items from the official datasheet and gives concrete next steps for validation, integration, and risk mitigation. The analysis emphasizes key specs and practical implications for RF connector selection and system margin planning.

#1 — Background: What the 1051098-1 datasheet documents (Background introduction)

1.1 Purpose & part family context

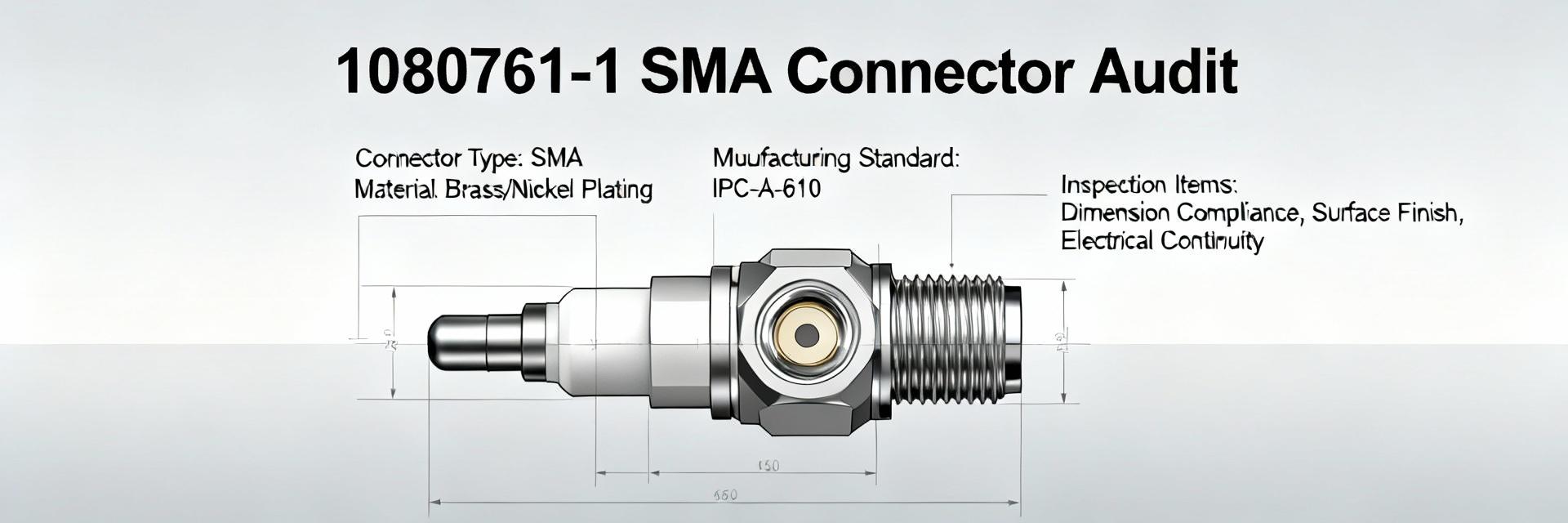

Point: The 1051098-1 is part of TE Connectivity's AMP RF/coax connector family intended for high-frequency interconnects in test, communications, and instrumentation. Evidence: The family groups connectors by mating interface, impedance, and mechanical style; the part number indicates family, variant, and plating/packaging information. Explanation: For selection, designers should treat the 1051098-1 as a 50 Ω RF connector intended where up to 18 GHz operation and robust mechanical retention are required. Next step: verify the mating interface and gender against mating parts in your BOM and request OEM packaging/part numbering clarification from the supplier to avoid mis-orders.

1.2 Datasheet sources & how to read them

Point: Prioritize the electrical table, mechanical drawing, ordering information, materials list, and qualification tests when reviewing the datasheet. Evidence: These sections list frequency limits, impedance, VSWR, dimensions, torque, plating, mating cycles, and environmental test results. Explanation: Start with the electrical table to define system margins, then confirm mechanical drawings for PCB footprint and mounting constraints, and finish with qualification tables to assess environmental suitability. Next step: compare the datasheet revision on the manufacturer page with distributor data before release to manufacturing; always request the latest revision or formal specification sheet from the OEM.

1.3 Key identifiers to note (part number, mating interface, gender)

Point: Critical identifiers are part number suffixes, mating interface type, gender, and stated impedance. Evidence: The datasheet calls out mechanical gender and mating face, which determine compatibility; impedance (typically 50 Ω) and the specified interface prevent mis-specification. Explanation: Mistakes often arise from mismatching gender/interface or selecting a wrong impedance variant; these cause high VSWR and poor insertion loss. Next step: record mating partner P/Ns, confirm impedance in BOM, and flag any variants with different plating or torque requirements for procurement controls.

#2 — Electrical key specs from the 1051098-1 datasheet (Data analysis)

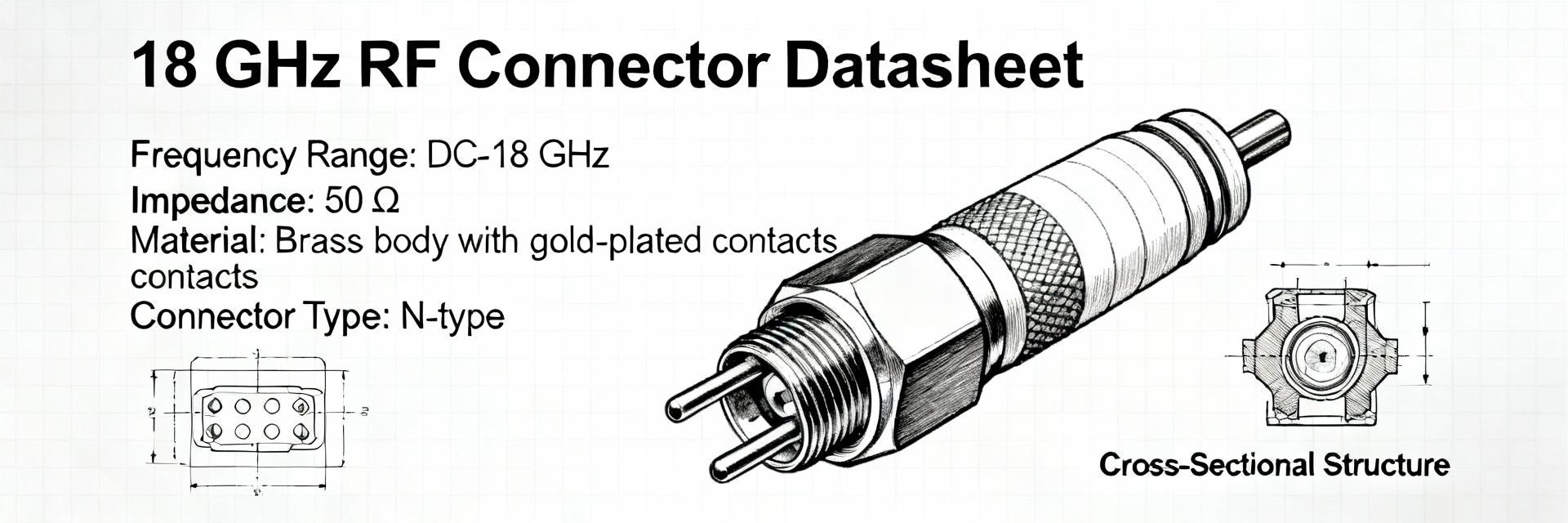

2.1 Frequency range, characteristic impedance & VSWR / return loss

Point: The connector is rated to 18 GHz with a nominal 50 Ω characteristic impedance; VSWR/return loss across frequency is the primary limiter for insertion loss and link budget. Evidence: Datasheet values typically show maximum frequency and a VSWR curve or table indicating acceptable return loss thresholds across the band. Explanation: A VSWR of 1.2–1.5 over the band corresponds to return loss of ~-20 to -14 dB; these values affect reflected energy and available margin. Next step: design margin by budgeting insertion loss and reflections — measure VSWR on a VNA with calibrated ports and ensure return loss stays within acceptable limits for your system (e.g., maintain return loss

2.2 Insertion loss, power handling & contact resistance

Point: Insertion loss and DC/contact resistance directly convert to system attenuation and potential thermal rise under RF power. Evidence: The datasheet provides insertion loss per connector (dB) versus frequency, DC contact resistance (mΩ), and sometimes rated voltage/current. Explanation: For example, a connector that contributes 0.2 dB at 10 GHz reduces link margin; multiple connectors or long cable runs multiply loss. Contact resistance affects DC and slow-varying heating; higher contact resistance can indicate wear. Next step: allocate an insertion loss budget for connectors (e.g., ≤0.5 dB total reserve per chain) and verify contact resistance during incoming inspection; reject parts outside specified mΩ tolerance.

2.3 Temperature, frequency-dependent behavior & derating

Point: Electrical performance varies with temperature—VSWR and insertion loss may degrade at extremes—so derating is necessary for high-power or extreme-temperature applications. Evidence: The datasheet lists operating temperature range and may show performance shifts across temperature. Explanation: Dielectric properties and contact resistance change with temperature; for high RF power, skin effect and conductor heating increase insertion loss. Next step: apply a derating factor for expected field temperatures (e.g., add 10–20% margin to insertion loss and validate at hot/cold extremes on a thermal chamber if operation approaches datasheet limits).

#3 — Mechanical & environmental specs (Data + method)

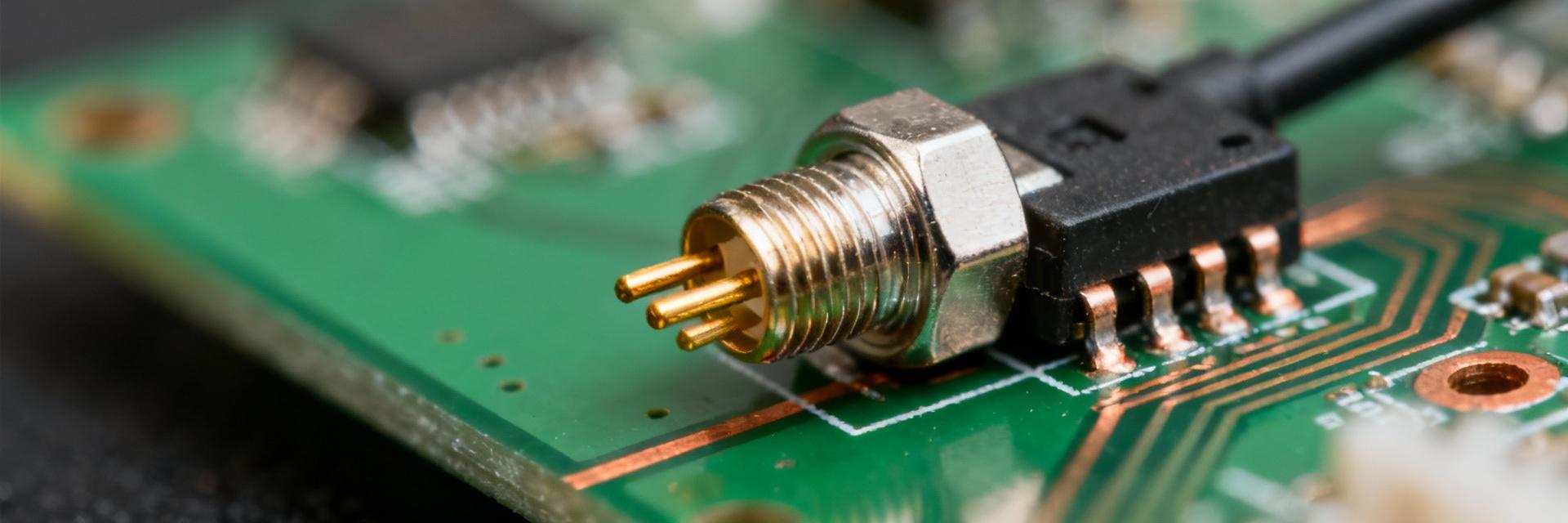

3.1 Mechanical dimensions, mating cycles, torque & mounting notes

Point: Mechanical callouts define PCB footprint, recommended torque, and rated mating cycles—these are essential for reliable mechanical integration. Evidence: Datasheet drawings provide mating interface dimensions and often specify torque in in-lb or N·m, plus rated mating cycles (e.g., 500–1000 cycles). Explanation: Incorrect torque or improper mounting leads to mechanical fatigue, poor contact, and intermittent RF behavior. Next step: follow the drawing for PCB keep-out, apply torque with a calibrated driver to the datasheet value during assembly, and qualify retained torque after environmental cycling.

3.2 Materials, plating & corrosion resistance

Point: Conductor and insulator materials plus plating determine long-term reliability—gold plating reduces fretting and contact resistance; nickel underplating protects against corrosion. Evidence: The datasheet lists materials for center conductors, outer conductors, insulators (PTFE, PEEK), and typical platings (gold over nickel). Explanation: Material choices affect fretting corrosion in vibratory environments and solderability for PCB-mounted variants. Next step: confirm plating finish and select corrosion-resistant finishes for outdoor or marine environments; if dissimilar metals are present, plan for potential galvanic issues and specify suitable environmental protection or conformal coatings.

3.3 Environmental qualifications: shock, vibration, sealing, and temp shock

Point: Qualification numbers (shock g, vibration profile, IP/sealing level, thermal shock cycles) indicate suitability for application classes like aerospace or outdoor base stations. Evidence: Datasheet qualification tables typically present shock (e.g., X g, Y ms), random vibration profiles, and any ingress protection ratings. Explanation: A connector that passed moderate vibration may still fail aerospace-level profiles; sealing ratings affect outdoor reliability. Next step: map the datasheet qualification levels to your application requirement matrix; if your environment exceeds listed tests, plan for additional validation or look to higher-rated alternatives.

#4 — Test, measurement & validation guidance (Method / actionable)

4.1 Recommended measurement setups for RF characterization

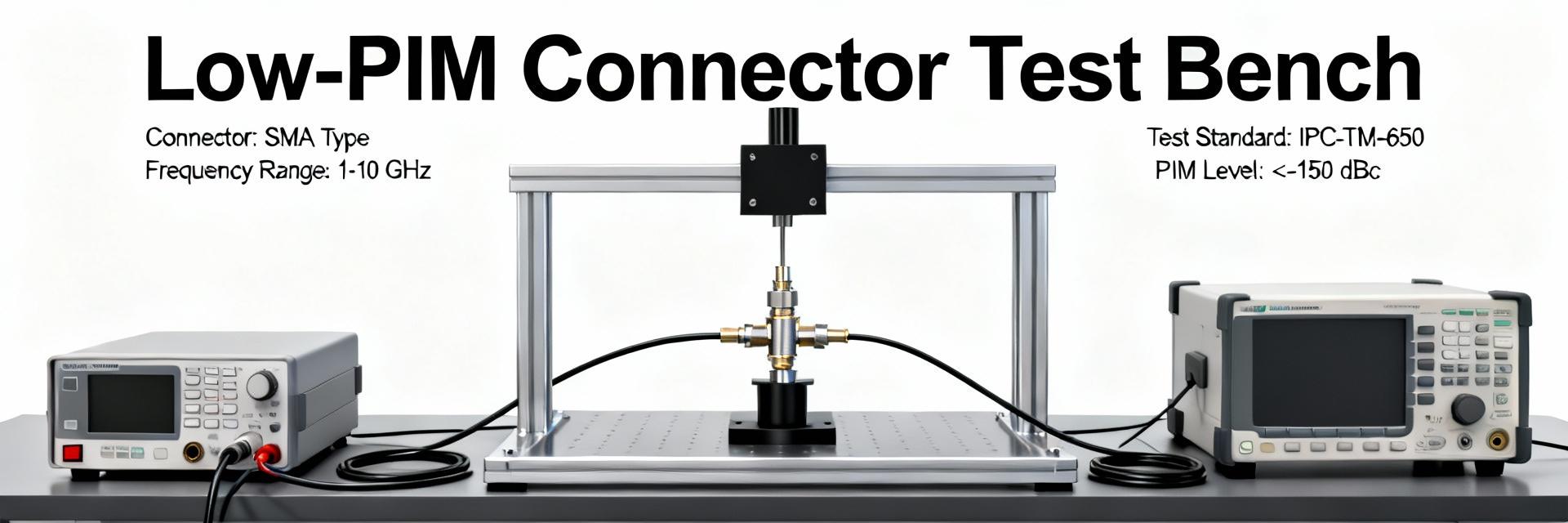

Point: Accurate RF characterization requires careful VNA calibration and minimized adapter chains to prevent measurement artifacts. Evidence: Measurement setups should use SOLT or TRL calibration up to 18 GHz, short, high-quality test fixtures, and defined port references. Explanation: Adapter chains introduce reflections that mask connector behavior; poor calibration yields misleading VSWR/insertion loss. Next step: perform a full two-port SOLT calibration to the connector interface, use high-quality torque-controlled mating fixtures, and include an adapter de-embedding step when necessary to isolate connector contribution.

4.2 Factory and field validation checklist

Point: A concise incoming and field verification checklist ensures parts meet datasheet claims before deployment. Evidence: Typical checks include visual inspection, dimensional verification, continuity/contact resistance measurement, insertion loss spot-check, return loss sampling, and torque verification. Explanation: Tolerances vs. datasheet define accept/reject thresholds—e.g., reject if return loss is >1.5× the worst-case datasheet value at a checked frequency. Next step: implement a 7-step check: visual, dimension, contact resistance, mating verification, insertion loss spot-check at key frequencies, torque audit, and batch sample VNA sweep to confirm compliance.

4.3 Failure analysis: common issues & troubleshooting steps

Point: Common failures include contamination, worn contacts, improper mating, and mechanical fatigue; structured troubleshooting isolates cause quickly. Evidence: Inspection often reveals debris on dielectric, fretting on contact surfaces, or loose mounting hardware. Explanation: Contamination raises insertion loss and VSWR; worn contacts increase contact resistance. Next step: inspect dielectric and contacts under magnification, clean per manufacturer guidance, re-torque per spec, confirm VNA signature before and after maintenance, and replace parts that fail to return to acceptable electrical performance.

#5 — Comparison, selection checklist & practical recommendations (Case study + action)

5.1 Quick comparison to similar TE parts / market alternatives

Point: Comparing close alternatives highlights trade-offs in frequency, VSWR, and mechanical robustness. Evidence: For example, a higher-frequency alternative may extend to 26 GHz with slightly higher VSWR; a lower-cost alternative may be limited to 12 GHz or fewer mating cycles. Explanation: Selection balances required max frequency, tolerated return loss, and budget. Next step: use the table below to compare typical contenders and choose the variant matching frequency and mechanical lifecycle needs.

| Part | Max Freq | Typical VSWR | Mating Cycles | Notes |

|---|---|---|---|---|

| 1051098-1 | 18 GHz | ≤1.5 | 500–1000 | Balanced high-frequency & robustness |

| Alt A (higher-freq) | 26 GHz | ≤1.6 | 300–500 | Extends band at cost of cycles |

| Alt B (cost-optimized) | 12 GHz | ≤1.4 | 200–500 | Lower cost, lower bandwidth |

5.2 Selection checklist for system designers (actionable)

Point: A prioritized checklist speeds objective selection and maps directly to datasheet entries. Evidence: Relevant checklist items: required maximum frequency, insertion loss budget, power handling, mating cycles, environment, footprint, supply constraints, and cost. Explanation: Each item ties to a datasheet field—for example, match required frequency to max frequency, map insertion loss budget to the insertion loss table, and verify mating cycles. Next step: walk down the checklist during design review and annotate the BOM with the corresponding datasheet line item for traceability.

5.3 Integration tips & procurement notes

Point: Procurement should order OEM part numbers, confirm revision, and request samples for validation; integration requires adherence to mount and torque specs. Evidence: Ordering generic equivalents increases risk of variant mismatch; mechanical notes in the datasheet determine footprint and panel cutouts. Explanation: Life-cycle issues arise if distributor stock is mixed across revisions. Next step: establish a procurement control: lock on the OEM P/N and revision, request a conformal sample test before volume buy, and maintain safety stock for long-lead items.

Summary

- The 1051098-1 datasheet shows suitability to 18 GHz with typical 50 Ω behavior — validate VSWR and insertion loss in your system band to confirm margin and ensure acceptable return loss at critical frequencies.

- Mechanical and materials details (torque, mating cycles, plating) dictate integration reliability — follow drawing callouts, torque specs, and material guidance to avoid fretting and mounting failures.

- Measurement and validation are essential: perform calibrated VNA sweeps, de-embed adapters, and apply temperature derating for high-power or extreme environments before production sign-off.

- Use the selection checklist to map system requirements to datasheet fields, compare close alternatives for trade-offs, and procure by OEM part and revision with sample validation to reduce risk.

FAQ

How does the 1051098-1 affect insertion loss in my RF chain?

Answer: The connector contributes a small but measurable insertion loss that increases with frequency. Datasheet tables give per-connector dB values that should be summed across the chain. Action: allocate a connector loss budget (for example, ≤0.5 dB total for all connectors in critical links), measure a sample batch on a calibrated VNA at your operating frequencies, and treat deviations beyond datasheet tolerance as a reject criterion.

What should I check in the 1051098-1 datasheet before specifying for outdoor use?

Answer: Confirm environmental qualification rows—temperature range, vibration, shock, and any sealing/IP ratings—and verify materials and plating for corrosion resistance. Action: if field conditions exceed datasheet tests, require additional ruggedization or select a higher-rated alternative; request manufacturer test reports or run supplemental environmental tests on samples.

How to test 1051098-1 RF connector performance during incoming inspection?

Answer: Incoming checks should include visual inspection, dimensional verification, contact resistance measurement, and a spot VNA sweep for insertion loss/VSWR at key frequencies. Action: define acceptance tolerances tied to datasheet numbers (e.g., return loss within +2 dB of datasheet worst-case) and implement batch sampling plans to catch out-of-spec lots before assembly.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606