-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

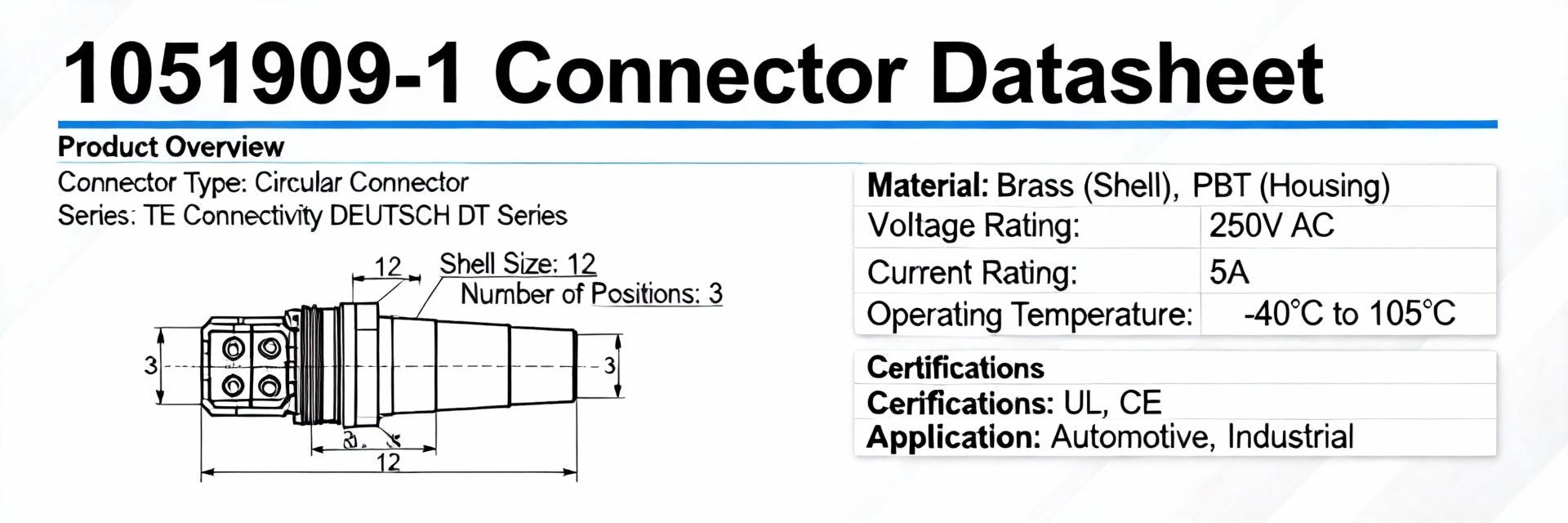

1051909-1 Datasheet: Complete Specs & Download Hub

Industry surveys show hardware engineers can spend up to 20% of a design cycle verifying parts and sourcing reliable datasheets — a single authoritative hub cuts that time and reduces rework. This guide consolidates the full 1051909-1 datasheet, core specifications, availability signals and safe datasheet download guidance for US-based engineers and procurement teams. It highlights where the part sits inside TE Connectivity’s portfolio, what to check on electrical, mechanical and environmental specs, and practical steps to verify vendor documentation before committing to PCB layout or production. Use this as an operational checklist to avoid substitution mistakes and procurement delays.

Background & Part Overview

Part number breakdown & identification

Point: The part number 1051909-1 follows TE Connectivity’s numeric schema and typically identifies a specific connector assembly within the AMP/TE family. Evidence: manufacturer catalogs and distributor entries list 1051909-1 as a discrete mating/contact assembly with known family cross-references. Explanation: break the number into its functional pieces—base family identifier, series index and suffix for termination or plating—so you can match alternate PNs or variants during cross-reference searches. Quick text summary (table-like): Form factor: circular/coaxial contact (confirm drawing); Series: AMP/TE interconnect family; Typical suffixes: -1 (standard finish), -2/-3 (alternate plating or termination). Validate suffix semantics on the master datasheet before procurement to avoid mismatched finishes or mounting styles.

Typical applications & industries

Point: This connector is used where robust signal or power connectivity is required in regulated environments. Evidence: similar TE AMP parts are specified in aerospace, commercial vehicles and industrial control equipment for high-reliability interconnects. Explanation: common use cases include vehicle harnesses, avionics interconnect panels and industrial sensor modules where vibration resistance and EMI control matter. Long‑tail example search term: 1051909-1 TE Connectivity AMP connector applications helps surface application notes and certification references; when evaluating suitability, confirm environmental ratings such as temperature range and any MIL-equivalent approvals listed on the datasheet.

Where it sits in TE Connectivity’s portfolio

Point: 1051909-1 is part of TE Connectivity’s AMP connector family and pairs with defined mating halves and accessories. Evidence: TE’s product family strategy groups mating components, backshells and seals under family trees to ensure mechanical and electrical compatibility. Explanation: when selecting mates and auxiliary parts, consult TE family indexes to find compatible receptacles, contacts and grommets. Look for related TE part numbers for mating plugs, backshells and contact kits in the family listing to ensure matched plating and current capability; selecting mismatched family members is a common source of field failures.

Complete Technical Specifications (data deep-dive)

Electrical specifications

Point: Electrical limits define safe operating envelopes and test criteria you must meet during validation. Evidence: authoritative datasheets present voltage ratings, current per contact, contact resistance, dielectric withstanding voltage and recommended electrical tests. Explanation: typical specification items to confirm on the master sheet include rated voltage (VAC or VDC), continuous current per contact (A), maximum contact resistance (mΩ at given test current), insulation resistance (MΩ at specified voltage), and dielectric withstanding voltage (Vrms or VDC with time). Always quote the test conditions (temperature, test duration, and applied test method) when documenting your design verification plan to match supplier test results to your system requirements.

Mechanical & dimensional data

Point: Mechanical drawings control footprint, mating interface and mounting decisions. Evidence: the datasheet provides pinout, mating interface details, mounting style and a full drawing set with dimensions and tolerances. Explanation: capture key dimensions (shell diameter, contact pitch, PCB pad pattern or panel cutout), mating force per connector pair, insertion/removal cycles and recommended torque for any threaded interfaces. Figure: key dimensions (see datasheet PDF page X). Note tolerances explicitly (e.g., ±0.1 mm or specified class) and compare the ECAD footprint to the manufacturer drawing before releasing fabrication files to avoid rework.

Materials, finishes & environmental ratings

Point: Materials and finishes determine corrosion resistance, temperature range and flammability behavior. Evidence: datasheet sections list contact metal and plating (e.g., copper alloy with gold or tin plating), insulator materials (thermoplastic or thermoset), operating temperature range and any IP or MIL-spec designations. Explanation: confirm contact plating thickness, insulator UL flammability rating, sealing method (O‑ring, gasket) and certified ratings such as IP6x or MIL‑STD equivalence where applicable. Use long-tail phrasing in procurement notes such as 1051909-1 datasheet PDF dimensions when recording mechanical checks to ensure CAD and supplier documents match exactly.

Lifecycle, Availability & Comparative Data

Stock status across major US distributors

Point: Live stock and lead-time signals at major authorized distributors determine procurement risk. Evidence: distributors like Digi‑Key, Mouser, Arrow and Octopart publish stock and lead‑time flags and often mirror manufacturer datasheets. Explanation: check distributor part numbers, quantity breaks and any obsolete/discontinued flags. When a listing shows “special order,” “factory lead time” or multiple lead‑time bands, flag the part for early buy. Use distributor notes to identify authorized channel sellers and avoid gray-market lots; when stock is low, request DIP (date code, lot traceability) details from the vendor.

End-of-life / replacement guidance

Point: Obsolescence forces either footprint-compatible replacement or redesign. Evidence: manufacturer cross‑reference tables and distributor supersession notes indicate direct replacements or recommended family shifts. Explanation: if 1051909-1 is marked discontinued, identify replacements that preserve electrical pinout and mechanical envelope; search by mating interface, contact count and mounting style. Decision logic: if replacement is pin‑compatible and environmental specs match, prefer part swap; if mechanical changes are needed, budget PCB and enclosure redesign and requalification testing.

Price history & procurement tips

Point: Price volatility affects BOM cost and sourcing strategy. Evidence: obsolete parts typically show higher per‑unit cost and greater lead-time variance. Explanation: mitigate risk by buying firm lots for production runs, qualifying multiple authorized distributors, and including alternate PNs in the BOM with approved change notices. For low-volume or legacy systems, consider long‑term agreements with suppliers or authorized brokers while verifying traceability and certification documents before purchase.

How to Download, Verify & Use the Datasheet (method guide)

Official TE Connectivity sources & verifying authenticity

Point: Always retrieve the master datasheet from TE Connectivity for authoritative specs. Evidence: the manufacturer PDF contains part-specific revision IDs, document numbers and revision/date metadata. Explanation: steps: search te.com for the part number, confirm the datasheet document ID and revision, inspect PDF metadata (author, creation date and revision notes) and compare the values you plan to use (voltage, current, dimensions) against the PDF. Use the phrase datasheet download in documentation to indicate you’ve retrieved the TE master copy and retained a date-stamped file for traceability.

Distributor & third-party mirrors (Mouser, Digi‑Key, Octopart, others)

Point: Distributor pages are convenient mirrors but can be outdated. Evidence: many distributor product pages cache manufacturer PDFs and list stock, but revision mismatches are possible. Explanation: when using a mirror, compare revision/date and at least two critical spec values (e.g., rated current and mating dimensions) against the TE master PDF. Note differences in ECAD model versions and ensure the distributor model matches the datasheet revision before importing into your library.

ECAD models, 3D CAD and library files

Point: CAD models speed PCB and mechanical integration but require validation. Evidence: TE provides ECAD libraries and 3D models; third‑party repositories may host alternate versions. Explanation: obtain the TE Library Loader or OEM 3D models and import using your EDA tool. Validate footprints by measuring key pad-to-pad dimensions against the mechanical drawing. Actionable tip: perform a 1:1 overlay of the ECAD footprint with the datasheet drawing before releasing Gerbers to the fab house.

Installation, Application Notes & Troubleshooting

Mounting, mating and torque recommendations

Point: Proper installation preserves contact reliability and lifetime. Evidence: datasheet sections list recommended torque values, mating order and handling notes. Explanation: follow the datasheet torque specs for any threaded shells or screws, observe proper mating/unmating cycles and use recommended backshells and strain reliefs. If the datasheet provides a mating sequence, adopt that order in assembly scripts to avoid misalignment and contact damage. Refer to the datasheet section for quoted torque numbers when documenting your assembly SOPs.

Common failure modes & inspection checklist

Point: Field failures often stem from contamination, improper mating or corrosion. Evidence: inspection procedures (visual, contact resistance) catch most assembly defects. Explanation: checklist: visual inspection for bent or damaged contacts, continuity testing across contacts under expected current, contact resistance measurement against datasheet max, and seal integrity checks if environmental sealing is required. Log inspection results with date-code to support warranty or failure analysis workflows.

Testing & validation best practices for design sign-off

Point: Design sign-off requires reproducible tests matching datasheet conditions. Evidence: recommended test regimes include environmental cycling, vibration, shock and electrical endurance tests described by the manufacturer. Explanation: include pass/fail criteria tied to the datasheet (no loss of continuity, contact resistance within specified limits, no dielectric breakdown at rated voltage). CTA: download the latest datasheet PDF before defining test parameters to ensure your test voltages, currents and cycles match the supplier’s specifications.

Summary

For authoritative information on 1051909-1 datasheet confirm the master PDF from TE Connectivity and cross-check distributor listings for stock and revision notes. Key specs to verify before design freeze include rated voltage and current per contact, mating dimensions and tolerances, contact materials and plating, and environmental ratings or approvals. Procurement best practice: confirm revision/date on the manufacturer PDF, prefer authorized US distributors and qualify a footprint by direct comparison with the datasheet before fab. Download the latest TE Connectivity datasheet and ECAD files from te.com or your authorized US distributor.

Key summary

- Verify the 1051909-1 datasheet master PDF from TE Connectivity and record the document ID and revision to ensure you use authoritative electrical and mechanical values in your design (voltage, current, dimensions).

- Confirm mechanical footprint and tolerances by overlaying ECAD models with the datasheet drawing—measure pad pitch, shell diameters and cutouts before issuing PCB files.

- Check materials and finishes (contact plating, insulator rating) against environmental requirements; sealing, temperature range and flammability class affect long‑term reliability.

- Assess distributor stock and lead times at authorized US distributors and plan procurement early; for obsolete parts, evaluate pin‑compatible replacements or redesign paths.

Common Questions & Answers

Where can I find the 1051909-1 datasheet?

Search TE Connectivity’s official site for the part number and download the manufacturer PDF to ensure you have the definitive document. Also verify distributor pages (Digi‑Key, Mouser, Arrow) for mirrored copies and stock information, but always compare the revision/date and key spec values to the TE master before using the data for PCB layout or test planning.

How do I verify the dimensions in the 1051909-1 datasheet PDF?

Open the TE PDF and locate the mechanical drawing; note the drawing reference and tolerances. Import the ECAD footprint and perform a 1:1 overlay or measure pad and cutout dimensions directly from the drawing. Confirm tolerances and note any min/max values; do not rely solely on third‑party models without this comparison.

What should I check in the 1051909-1 datasheet before production?

Confirm electrical ratings (voltage/current), contact resistance limits, environmental and sealing ratings, materials and finishes, recommended mounting/torque values and specified mating cycles. Record the datasheet revision and keep the PDF with your BOM and validation test plan to ensure traceability during production and field support.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606