-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1254028-1 Datasheet Breakdown: Specs & Compliance Guide

Point: Careful datasheet review significantly reduces connector-related field failures and procurement rework; this guide focuses on practical validation steps for the 1254028-1 datasheet and related connector specs. Evidence: Industry analyses indicate that methodical datasheet analysis and supplier verification can cut connector-related failures and design rework by up to 40%, driving measurable program reliability and cost savings. Explanation: For US-based engineers and procurement teams, that translates into fewer line-replaceable-unit swaps, lower warranty exposure, and faster time-to-first-article acceptance when the datasheet is parsed against system requirements early in the acquisition cycle.

Point: This document is written to be actionable and test-driven for design, test, and procurement stakeholders. Evidence: Practices described here align with aerospace and RF connector guidance found in standard supplier catalogs and RF connector reference materials used across defense and commercial programs. Explanation: Use this guide to rapidly triage the 1254028-1 datasheet against mechanical interfaces, electrical/RF performance, environmental qualifications, and contractual controls so teams can avoid common integration pitfalls and ensure acceptance criteria are traceable.

1 — What is 1254028-1 and when to choose it (Background)

Part identity & family context

Point: Understand the part family and manufacturer context before sizing it into your system; a correct identity check prevents cross-mating and performance surprises. Evidence: Catalogs and aerospace connector references commonly group precision RF connectors and ruggedized coaxial interfaces by series and prefix/suffix conventions; typical datasheets list manufacturer, series, and compatible mating families in the introductory block. Explanation: For the 1254028-1 lineage, treat the datasheet header and ordering information as the authoritative source for series, mating interfaces and variant codes (plating, insulator, special finishes). Cross-check the manufacturer part-number format (base PN + suffixes for finish/packaging) against approved vendor lists and internal BOM nomenclature to avoid substituting non-equivalent items during procurement.

Key datasheet sections to scan first

Point: Prioritize a short set of datasheet sections for an immediate go/no-go assessment. Evidence: High-impact sections typically include mechanical drawings, electrical ratings, materials/finishes, environmental limits, and test/qualification tables; these sections define interchangeability and system fit. Explanation: Quick-scan checklist (in order): 1) mechanical drawings & mounting interfaces, 2) electrical/RF specs (impedance, VSWR, voltage/current), 3) materials & plating notes (RoHS, corrosion), 4) environmental ratings and qualification tests, 5) ordering codes and variants. If any critical value is missing or ambiguous, escalate to supplier clarification before prototype release.

Common procurement triggers

Point: Procurement should flag common contract and supply issues early. Evidence: Typical triggers in RF/aerospace sourcing include long lead times, special plating or plating thicknesses, minimum order quantities (MOQ), and AV/AVL constraints; many supplier datasheets also include RoHS/REACH declarations and ordering lead-time disclaimers. Explanation: Quick verification steps: cross-check MFG PN against your AVL, request RoHS/REACH and material declarations, confirm plating thickness and finish code, verify MOQ and lead time, and require sample first-article tests where contractually required. Include a clause for supplier lot traceability and date-code stamping in purchasing orders to simplify incoming inspection.

2 — At-a-glance specs: mechanical, materials & form factor (Data analysis)

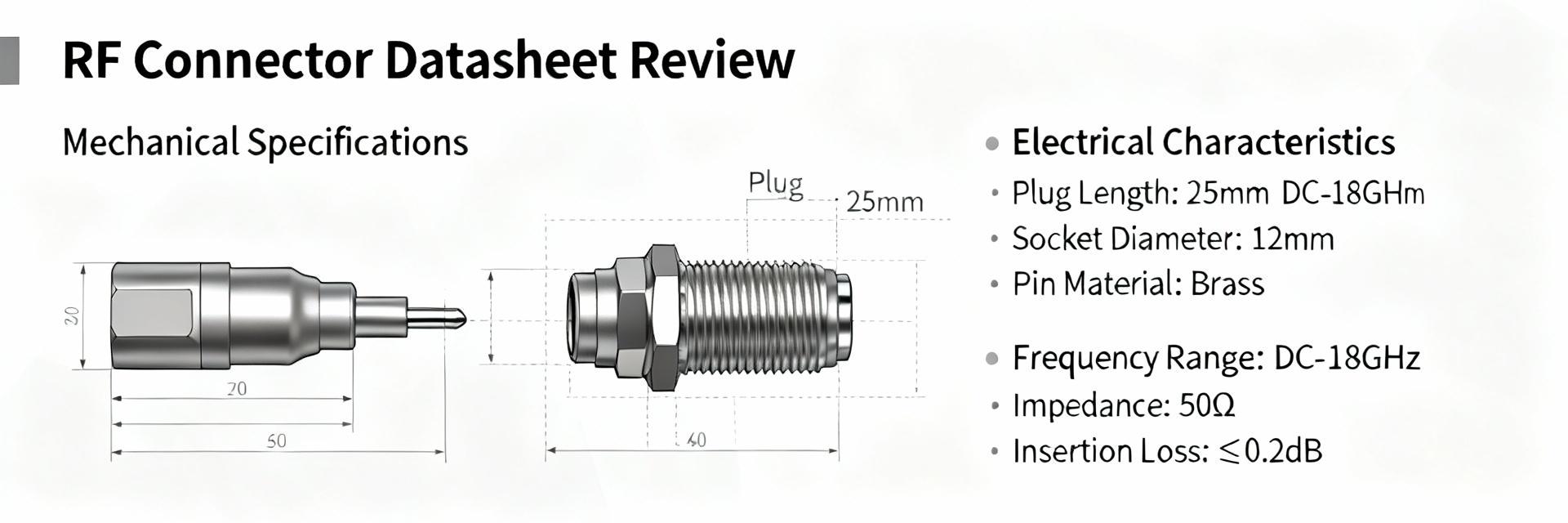

Mechanical dimensions & tolerances

Point: Mechanical dimensions and tolerance callouts determine interchangeability and mounting reliability. Evidence: Datasheet drawings typically provide a critical-dimension table and tolerance block; even small OD/ID or mounting-hole shifts can cause misalignment that degrades RF performance or prevents assembly. Explanation: Read drawings for: mating face geometry, center conductor position, PCB footprint or panel-cutout, threaded engagement length, and concentricity tolerances. Annotated comparison table (example) helps identify which dimensions are critical for your design review and which fall into permissive fit ranges.

| Parameter | Critical Range / Note |

|---|---|

| Center conductor offset | <0.05 mm; affects VSWR at upper band |

| Mating depth | ±0.2 mm tolerance; impacts contact retention and torque |

| Panel cut-out | per datasheet; deviation may require custom hardware |

Materials, finishes & corrosion resistance

Point: Materials and plating choices drive contact resistance, wear life, and environmental robustness. Evidence: Typical datasheets specify contact materials (beryllium copper, phosphor bronze), insulators (PTFE, PEEK), and plating (gold flash, 2–30 µin gold, nickel underplating). Explanation: For signal-critical or high-reliability applications prefer gold-plated contact surfaces for low contact resistance and corrosion resistance; nickel underplating is common but can increase contact resistance if plating defects occur. Evaluate salt-spray suitability and humidity performance; if the datasheet omits salt-spray hours or corrosion class, request supplier testing or a higher-grade finish for marine/coastal deployments.

Mechanical performance (durability, torque, retention)

Point: Mechanical performance metrics—mating cycles, torque specs, retention forces—are acceptance drivers for both design and maintenance. Evidence: Datasheets normally list specified mating cycles (e.g., 500–2000 cycles), insertion/extraction forces, and recommended torque for threaded connections. Explanation: Confirm mating cycle specification aligns with expected field handling and maintenance intervals; for threaded/locking features, follow torque sequences to avoid contact deformation. Where ruggedization is needed, select variants with vibration locking or increased retention force and document rework limits (replacement after X mating cycles) in maintenance procedures.

3 — Electrical & RF connector specs deep-dive (Data analysis)

Voltage, current, insulation & dielectric ratings

Point: Electrical insulation and dielectric ratings set safe operating margins and determine system-level derating strategies. Evidence: Datasheet entries typically present dielectric withstanding voltage, working voltage, insulation resistance, and creepage/clearance distances relative to material and geometry. Explanation: Translate datasheet dielectric withstanding voltage into system derating: if the connector lists 1,000 VDC withstand, apply safety factor (commonly 2× for transient scenarios) and confirm creepage/clearance for intended altitude and contamination class. Use insulation resistance values to detect process contamination at incoming inspection; specify pass/fail thresholds tied to the datasheet values.

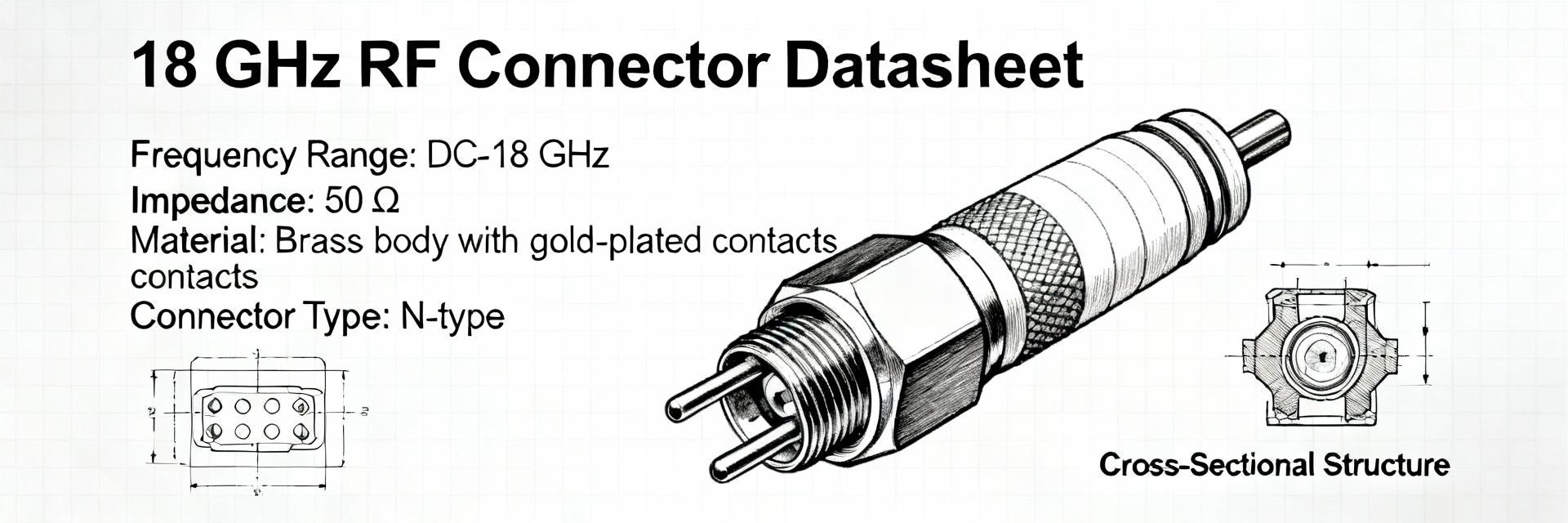

RF performance: impedance, VSWR/return loss, frequency range, insertion loss

Point: RF parameters determine link budget and matching across intended frequency ranges. Evidence: Datasheet RF tables normally define characteristic impedance (50 Ω vs 75 Ω), maximum frequency, VSWR/return loss across bands, and insertion loss per unit length or per mated pair under specified test conditions. Explanation: Validate that the connector's rated frequency range and VSWR limits meet system S-parameter budgets; if the datasheet provides test-condition S-parameter graphs, confirm temperature and fixture conditions. For narrowband high-power or high-frequency designs, require S11/S21 plots for your actual test-fixture to avoid surprises from fixture-induced reflections.

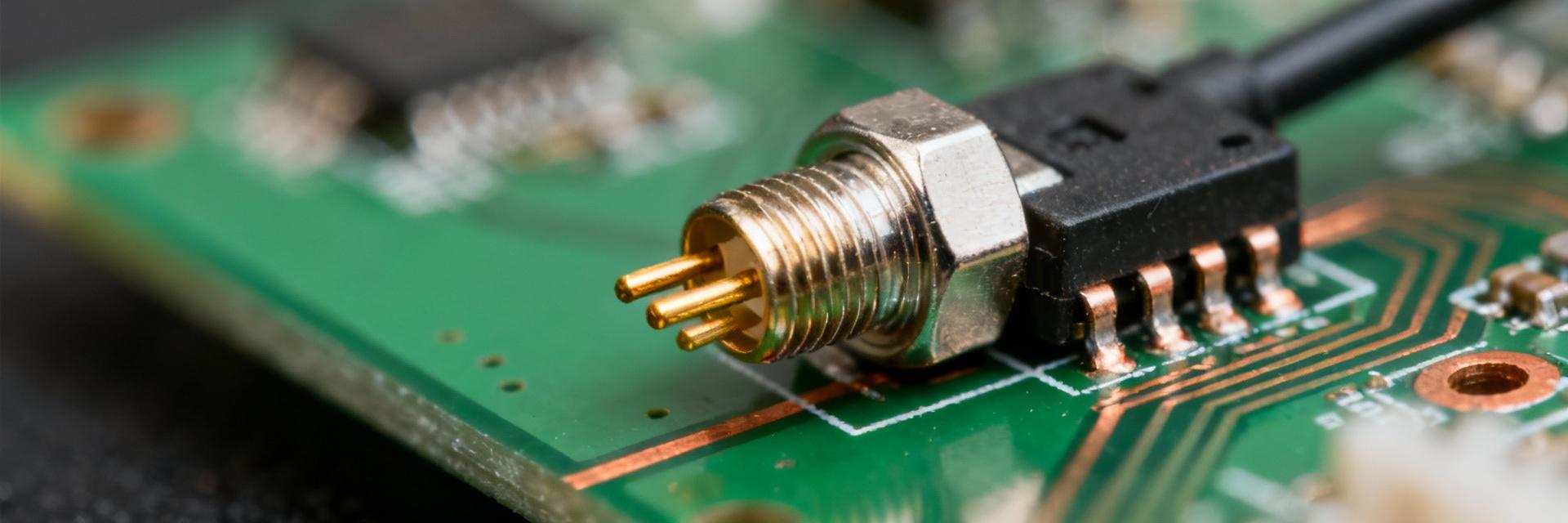

Contact resistance, continuity & signal integrity impacts

Point: Contact resistance and plating materially affect low-level signal integrity and noise performance. Evidence: Datasheets list initial and aged contact resistance, and sometimes provide resistance after endurance cycles and environmental exposure. Explanation: Use contact resistance and plating details to model connector contribution to insertion loss and potential DC voltage drop in power contacts; factor increased resistance after salt-spray or mating cycles in worst-case SI models. Where differential pairs or high-speed signals are present, incorporate connector parasitics into end-to-end SI simulations (S-parameter embedding) and specify acceptable degradation limits in procurement documents.

4 — Compliance, standards & regulatory mapping (Method guide)

Common standards to check (MIL, IEC, RoHS, REACH, UL)

Point: Map datasheet line items to applicable standards to prove suitability in regulated applications. Evidence: Supplier datasheets for aerospace/defense products commonly reference MIL-C specifications, IEC test procedures, RoHS/REACH compliance statements, and UL recognition where applicable. Explanation: Create a standards mapping table tying each datasheet entry (temperature range, insulation resistance, flammability rating, plating process) to the relevant clause in MIL, IEC, or UL standards; require supplier certificates of conformance and cross-reference the clause numbers in procurement records to support audits.

| Datasheet Item | Standard/Clause | Evidence to Request |

|---|---|---|

| Temperature range | MIL-STD temp classes / IEC 60068 | Qualification test report |

| RoHS statement | RoHS Directive (as adopted) | RoHS declaration or material cert |

| Shock & vibration | MIL-STD-810 / MIL-STD-202 | Environmental test data |

Environmental qualification & performance classes

Point: Environmental classes (temperature, altitude, shock/vibration) must align with the end-use profile. Evidence: Datasheets list operational and storage temperature ranges, and often include altitude/vacuum or shock/vibration class statements for aerospace-rated parts. Explanation: Map intended application profile (e.g., avionics bay, unpressurized exterior, shipboard) to the datasheet classes; if the part lacks a published altitude or vacuum rating, require supplier testing for the expected environment or select a part with explicit qualification.

Export controls, ITAR/EAR and contractual compliance

Point: Some connector types used in defense systems are export-controlled; procurement must screen early. Evidence: Contract and supplier declarations should note ITAR-controlled designs or EAR licensing requirements for certain components and technologies. Explanation: Escalate to program legal/compliance when the datasheet indicates specialized alloys, controlled cryptographic interfaces, or explicit defense-market positioning; include export-control clauses and escalation steps in RFQ templates for defense/space contracts to avoid shipment delays or license violations.

5 — Testing, validation & qualification workflow (Method guide)

Recommended lab tests & acceptance criteria

Point: Establish a prioritized test list with pass/fail criteria derived from the datasheet. Evidence: Typical lab tests include continuity, insulation resistance, dielectric withstand, VSWR/S-parameter sweeps, environmental cycling, and salt-spray. Explanation: Tie acceptance thresholds to datasheet values: e.g., insulation resistance ≥ datasheet min; dielectric withstand ≥ datasheet value × safety margin; VSWR within datasheet limits across rating band. Document test fixtures, calibration data, and traceability for each test to support supplier claims and first-article acceptance.

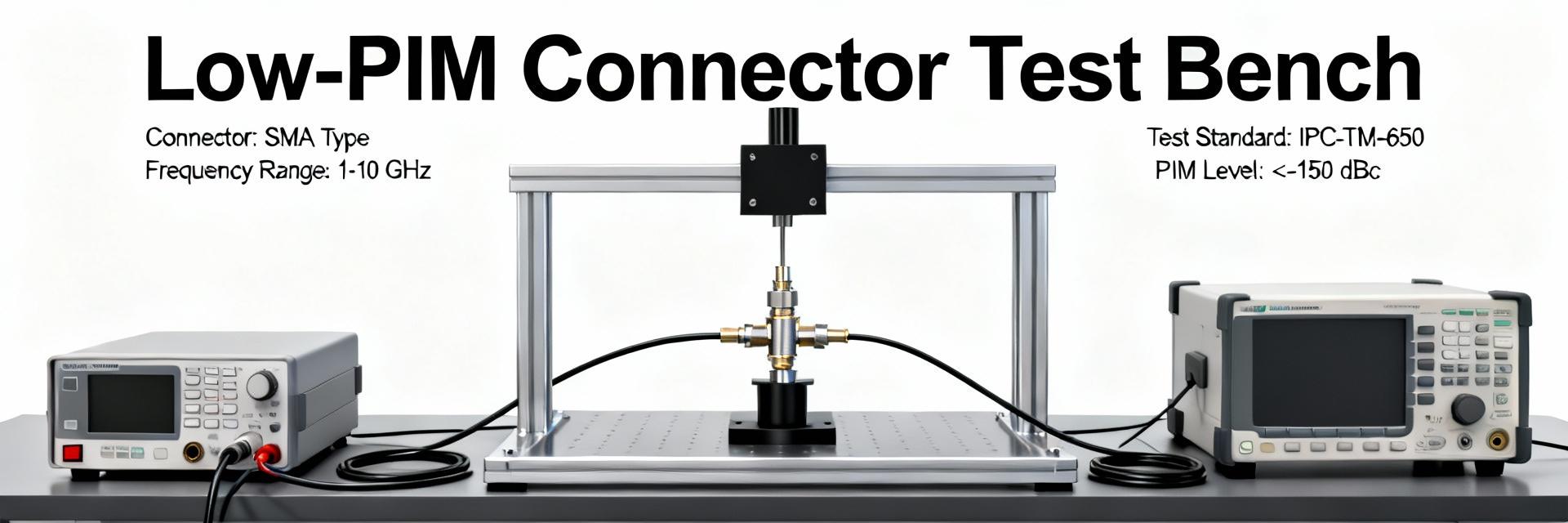

In-system validation & test-fixture considerations

Point: Fixtures and test conditions materially affect RF results; design fixtures to reflect in-system behavior. Evidence: S-parameter measurements are sensitive to fixture impedance, cable length, and connector adaptation; datasheets often report test-fixture conditions because measurements are not absolute. Explanation: For in-system validation, use fixtures that replicate mounting, grounding, and cable routing; characterize fixture contributions with a known reference connector and subtract fixture S-parameters (calibration). Avoid connector-cable mismatch by using proper adapters and account for cable reflections during analysis.

Supplier test reports, lot traceability & incoming inspection

Point: Require supplier documentation to support batch acceptance and traceability. Evidence: Best practice calls for test reports with date codes, material certs, plating thickness verification, and lot-level continuity/VSWR data for each shipment. Explanation: Include a sample inspection plan with percentage sampling for visual, dimensional, and electrical checks; require supplier NDT records and a certificate of conformance tied to lot numbers. Store incoming inspection records in configuration management to support failure investigations and warranty claims.

6 — Installation, troubleshooting & procurement checklist (Action + Case)

Installation best practices & handling precautions

Point: Correct installation preserves performance and service life. Evidence: Datasheets provide torque specs, mating sequences, and handling warnings; deviation from recommended torque or contamination control is a frequent root cause of field issues. Explanation: Follow torque sequences for multi-connector assemblies, use anti-rotation washers where specified, maintain clean handling environments (lint-free, glove use) to prevent dielectric contamination, and use correct tool calibration. Document rework limits—replace connectors after exceeding the datasheet mating-cycle limit or after visible plating wear.

Common failure modes & troubleshooting workflow (mini case)

Point: Rapidly isolating failures reduces system downtime. Evidence: Two common cases—intermittent contact from plating wear and elevated VSWR from misalignment—occur in field returns and are well-documented in failure analyses. Explanation: Example workflows: Problem → diagnostics → corrective actions. Case A: Intermittent contact → perform contact resistance and continuity tests → replace worn contacts or switch to higher-grade plating. Case B: Elevated VSWR → inspect mating alignment and torque, run S11 measurement with known-good fixture → correct seating, replace damaged connectors, or adjust PCB cutout tolerances.

Procurement & acceptance checklist (ready-to-use)

Point: A one-page checklist standardizes buying and incoming QA. Evidence: Effective checklists include PN verification, certifications, test reports, sampling plans, packaging checks, and shelf-life notes; these elements are reflected in vendor datasheets and procurement best practices. Explanation: Use the checklist below during purchase order creation and incoming inspection to ensure the supplier delivers parts that match the technical and contractual expectations.

- Verify exact PN and variant codes against datasheet ordering information and AVL.

- Obtain RoHS/REACH declaration, material certificates, and plating thickness data.

- Request supplier test reports for continuity, dielectric, and RF (S-parameters) with date codes.

- Specify lot traceability, packaging, and environmental storage conditions.

- Define sample inspection plan and first-article acceptance criteria tied to datasheet values.

Summary

Point: A disciplined review of the 1254028-1 datasheet across mechanical, electrical and compliance domains prevents field failures and procurement delays; include connector specs in early trade studies and procurement documents. Evidence: Matching mechanical interfaces, RF parameters, and qualification claims against system requirements and contract standards reduces rework and supports timely acceptance. Explanation: Action items: download and archive the datasheet for configuration control, request supplier test reports for critical lots, and run the provided procurement checklist during purchasing and incoming inspection to minimize integration risk and program impact.

Key summary

- Mechanical fit drives interchangeability: verify center-conductor position, mating depth and panel cut-out tolerances against your assembly to avoid misalignment and VSWR issues.

- Materials and plating determine long-term contact resistance and corrosion resistance—request plating thickness and salt-spray performance when deployed in corrosive environments.

- Electrical and RF specs (impedance, VSWR, dielectric withstand) must be mapped to system derating rules and S-parameter budgets during early validation planning.

- Compliance mapping (MIL/IEC/RoHS) and supplier test reports are required intake items for procurement to meet audit and export-control obligations.

- Use the procurement checklist for PN verification, lot traceability, first-article testing, and sample inspection to reduce field failures and schedule risk.

Frequently Asked Questions

What should I look for first in the 1254028-1 datasheet?

Point: Start with mechanical drawings, electrical ratings, and material/finish notes. Evidence: These sections determine fit, signal performance, and corrosion resilience which are common root causes of failure when overlooked. Explanation: Quick-scan the datasheet for mating interface dimensions, impedance and VSWR limits, and plating/insulator materials; if any are missing or ambiguous, request clarification from the supplier before prototype fabrication.

How do connector specs in the 1254028-1 datasheet affect RF performance?

Point: Connector geometry, contact plating, and tolerance stack-ups influence impedance, return loss, and insertion loss. Evidence: S-parameters reported in datasheets depend on test fixtures and temperature; mismatches in mechanical alignment or plating wear increase VSWR. Explanation: Incorporate connector parasitics into SI models, validate with in-system S-parameter measurements, and require supplier-provided S11/S21 plots on fixtures as part of the acceptance package.

What incoming inspection steps should reference the 1254028-1 datasheet?

Point: Incoming inspection should validate PN, dimensions, plating, and electrical/RF performance per the datasheet. Evidence: Best practice inspection plans include dimensional checks, contact resistance, insulation resistance, and sample VSWR/continuity tests tied to supplier reports. Explanation: Implement a plan that cross-references datasheet thresholds, requests lot-level test data, and captures date codes/traceability to simplify failure analysis and supplier escalation.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606