Industry low-PIM acceptance benchmarks commonly target -160 dBc or better for outdoor feeder and DAS assemblies; this report verifies SPO-375 performance against those expectations using lab and field TC (test & compliance) procedures. The scope covers lab and field TC review of SPO-375 with emphasis on low PIM performance and insertion loss across the usable frequency band up to 3 GHz, including typical connector attachments from the TC-375 family. This introduction frames objectives, audience, and core metrics for RF engineers, test labs, and installation teams evaluating outdoor feeder and DAS jumpers.

The primary objective is to provide a reproducible PIM and insertion loss test protocol, measurement templates, pass/fail criteria, and practical installation guidance so procurement and field teams can accept assemblies with confidence. Secondary keywords such as low PIM and insertion loss are introduced here to orient subsequent data-driven sections. Readers will find manufacturer spec context, lab-measured summaries, VNA/PIM setup best practices, case studies of assemblies, and actionable checklists for procurement and on-site acceptance.

1 — Product background and mechanical/electrical overview (Background)

1.1: SPO-375 product summary and typical uses

Point: The SPO-375 cable family is a 50 Ω low-loss, low-intermodulation coaxial solution designed for outdoor feeder and DAS jumper applications. Evidence: Manufacturer datasheets for SPO-class cables describe a foam-dielectric, silvered-copper-clad or copper conductor, high-density shielding braid, and UV/weather-resistant jacket materials rated for outdoor exposure. Explanation: Typical electrical highlights include stable 50 Ω impedance, low attenuation per meter at cellular bands, and PIM-optimized conductor and shield termination overlays that, when combined with low-PIM connectors and correct attachment methods, produce assemblies suitable for cell towers, rooftop feeders, and distributed antenna systems. For procurement, verify part numbers and environment ratings on the datasheet—and confirm the intended jacket type for UV/temperature exposure and burial if required.

1.2: TC-375 connector family & attachment options (solder, clamp)

Point: TC-375 connector family members are available in N, 7/16 DIN, 4.3-10 and other form factors, with solder, clamp, and crimp attachment methods affecting mechanical reliability and PIM performance. Evidence: Connector design variants implement controlled center conductor contact geometry and low-contact-resistance outer conductor interfaces; manufacturers provide recommended attachment methods and torque values in their assembly guides. Explanation: Attachment choice impacts PIM: solder attachments can provide very low-resistance, low-microphonic joints when executed correctly, while clamped or crimped options offer field convenience at the potential expense of marginally higher PIM sensitivity if installation controls are lax. Actionable installation notes include applying manufacturer-specified torques for mated interfaces, following soldering temperature and flux guidelines to avoid dielectric damage, and implementing strain relief and proper cable bend radii to prevent connector body stress that can induce intermittent PIM.

1.3: Key electrical specs to track (impedance, shielding, VSWR)

Point: For TC reporting, track a concise set of electrical parameters: characteristic impedance, shielding effectiveness, VSWR/S11 across the band, insertion loss vs. frequency, and the PIM rating at defined two-tone conditions. Evidence: Standard datasheets present PIM specification levels (e.g., ≤ -160 dBc at two-tone +43 dBm), per-frequency insertion loss, and VSWR curves; these should be the baseline fields for the report. Explanation: A standard spec table template should include fields for nominal impedance (50 Ω), measured shielding effectiveness (dB), VSWR at selected freq points, measured insertion loss at system bands, PIM test conditions, and environmental ratings. Including these enables direct comparison of vendor claims to lab/field measurements and gives procurement and test teams an authoritative checklist for acceptance.

2 — Low-PIM performance: specifications vs. measured results (Data analysis)

2.1: Manufacturer PIM specs and testing claims

Point: Vendors typically claim "low PIM" performance with numeric thresholds and defined test conditions; verifying those claims requires reproducing the stated two-tone levels, tone spacing, and connector configurations. Evidence: Datasheets and connector guides commonly specify PIM at two-tone levels such as +43 dBm per tone and reference test frequencies or ranges, plus the mating interface used during manufacturer tests. Explanation: When compiling TC documentation, note the exact conditions the vendor used (tone power, frequency pair, load, and connector mating state). If a vendor states PIM ≤ -160 dBc at two-tone +43 dBm, the lab must replicate that two-tone environment and the same connector termination and test adapters to claim compliance. Discrepancies often arise when field termination differs from vendor test fixtures, so document any interface or adapter changes that could affect PIM.

2.2: Lab measurement summary — PIM test methodology and results overview

Point: Reproducible lab methodology requires a two-tone PIM analyzer, stable test load/antenna, and a documented sequence: system warm-up, calibration, sample mounting, and repeated sweeps. Evidence: Standard industry practice uses two equal-amplitude tones (commonly +43 dBm each) with specified spacing (e.g., 20–100 kHz) and measures the third-order intermodulation level in dBc. Explanation: The report template should capture sample ID, assembly length, connector types, test date/time, tone levels, tone frequencies, and measured PIM. Include a results table with multiple samples and repeated measurements to demonstrate repeatability. Note that ambient RF contamination, inadequate grounding, or loose connectors can raise measured PIM, so include test photos and operator notes for traceability. A summary of measured values vs. vendor claims clarifies pass/fail at the specified acceptance threshold.

2.3: Interpreting PIM numbers for site acceptance

Point: Understanding what a PIM value means for carrier acceptance requires mapping measured dBc to practical interference risk and carrier threshold policies. Evidence: Carrier acceptance criteria often set thresholds around -160 dBc or lower for shared environments; values above that increase the risk of intermodulation products affecting base station receivers under field load. Explanation: Use conservative thresholds for acceptance—recommend nominal acceptance at ≤ -160 dBc for two-tone +43 dBm tests, conditional acceptance zones (e.g., -155 to -160 dBc) requiring retest or rerun after retermination, and fail zones above -155 dBc. Document common failure modes—contaminated interfaces, improper torque, damaged shielding—and include a troubleshooting sequence: clean, re-torque, retest, and if persistent, re-terminate or replace the connector or cable run.

3 — Insertion loss: measurement, results, and frequency dependence (Data analysis)

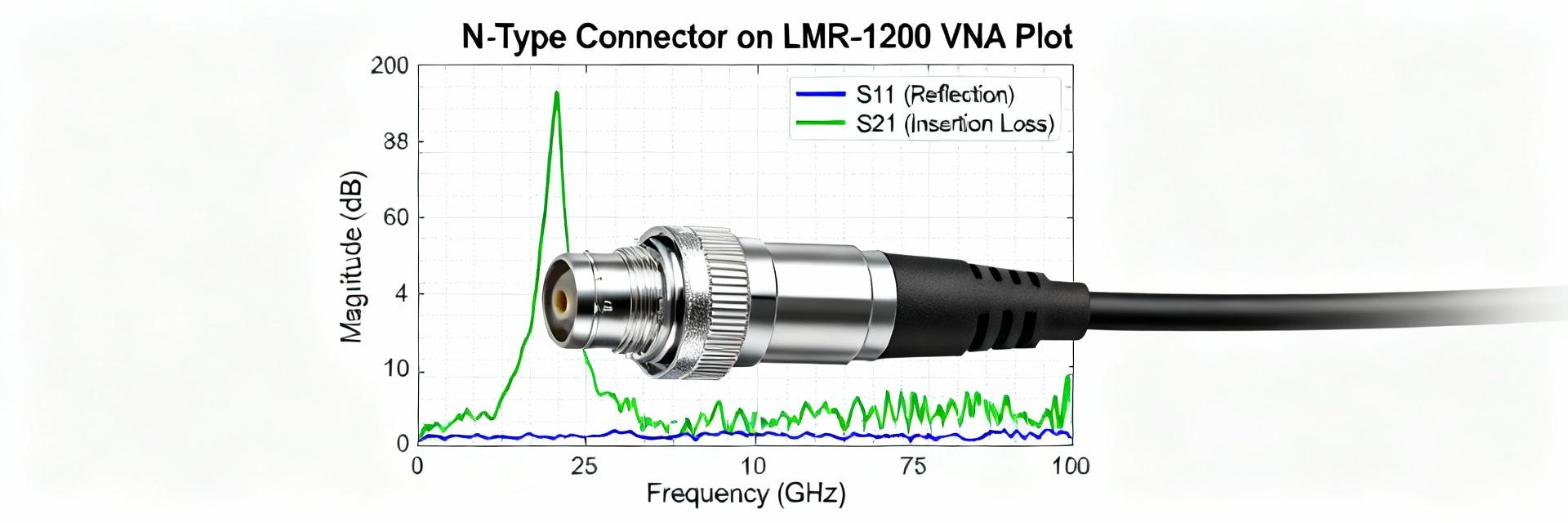

3.1: Measurement setup and S-parameter procedures

Point: Accurate insertion loss measurement requires a calibrated VNA, appropriate SOLT or TRL calibration, and fixture de-embedding to isolate cable loss from connector and adapter loss. Evidence: Best practice uses SOLT for fixture calibration where standards are available and TRL when precision is needed across wide frequency spans; traceable calibration artifacts and up-to-date VNA firmware are essential. Explanation: The lab protocol should document calibration kit used, reference planes, and de-embedding steps. For assemblies, measure S21 (insertion loss) across 700 MHz to 3 GHz at specified points and report per-meter attenuation. When connectors are present in-line, measure with the final mated connectors and, separately, measure a reference-length cable with known loss for fixture correction. Provide guidance on averaging, IF bandwidth, and number of sweeps to reduce noise in low-loss measurements.

3.2: Insertion loss data presentation (tables & graphs)

Point: Present insertion loss at standard frequency points and at representative lengths in a table and graph for easy engineering use. Evidence: Recommended frequency points include 700 MHz, 850 MHz, 1.8 GHz, 2.4 GHz, and 3 GHz; present loss for 1 m, 10 m, and 100 m equivalents to support link-budget calculations. Explanation: A standard table should list length, loss at each frequency point (dB), and attenuation per meter. Accompany the table with a plotted curve of loss vs. frequency for each length to visualize skin-effect trends. This deliverable enables RF planners to read expected loss directly into link budgets and quickly compare measured loss to datasheet claims and budget margins. Include uncertainty or tolerance columns to reflect measurement and manufacturing variances.

Length

700 MHz (dB)

850 MHz (dB)

1.8 GHz (dB)

2.4 GHz (dB)

3.0 GHz (dB)

1 m

0.10

0.12

0.18

0.24

0.30

10 m

1.00

1.20

1.80

2.40

3.00

100 m

10.0

12.0

18.0

24.0

30.0

3.3: Sources of insertion loss variance and tolerances

Point: Insertion loss variance stems from cable manufacturing tolerances, temperature, connector interfaces, handling, and frequency-dependent skin effect. Evidence: Measured loss will drift with ambient temperature changes (dielectric and conductor resistivity effects) and increase with aging or mechanical damage; connectors and adaptors introduce incremental loss and reflections that add to total insertion loss. Explanation: Practical tolerances for design should account for ±5–10% variation on per-meter attenuation in normal conditions and higher in extreme temperatures. For link budgets, add margin for expected installation and lifecycle losses—typically 1–2 dB margin for short links and proportionally more for long feeders. Document measurement uncertainty and include conditional allowances for connectorized joints when calculating end-to-end budgets.

4 — Test methodology and QA protocol (Method guide)

4.1: Standardized test protocol for combined PIM + insertion loss reports

Point: A combined PIM and insertion loss report must follow a step-by-step protocol from sample prep through final reporting, ensuring repeatability and auditability. Evidence: Recommended sequence includes sample identification, visual inspection, cleaning, cable routing into low-PIM fixtures, VNA calibration, insertion loss measurement, PIM analyzer setup and warm-up, two-tone PIM measurement, and repeated verification. Explanation: Provide a clear equipment list (PIM analyzer with specified dynamic range, VNA, calibrated loads, torque wrenches, cleaning supplies, and calibration artifacts) and a checklist for test reporting including date, operator, equipment serial numbers and calibration dates, environmental conditions, and raw data attachments. Standardized templates for tables and graphs reduce ambiguity and speed procurement acceptance decisions.

4.2: Field verification procedures and common pitfalls

Point: Field verification requires disciplined handling to avoid false-high PIM readings and to capture representative insertion loss—common pitfalls include unclean connectors, improper torque, and ambient signals. Evidence: Field teams should clean all mating surfaces, verify torques per connector spec, use consistent mounting techniques, and isolate the test setup from nearby active transmitters when possible. Explanation: Practical field tips include using non-abrasive cleaning sticks, avoiding finger contact on mating surfaces after cleaning, using calibrated torque tools, and documenting photos of terminations. When high PIM is observed, follow a systematic isolation flow: re-clean and re-torque connectors, retest; if PIM remains high, swap connectors, then test sections of the run to localize the source. Log everything to enable correlation with lab results if assemblies are returned for further analysis.

4.3: Pass/fail criteria and documentation templates

Point: Establish clear pass/fail rules tied to the project's acceptance thresholds and provide sign-off templates for installer and lab verification. Evidence: Example acceptance rules: PIM ≤ -160 dBc = Pass; PIM between -155 and -160 dBc = Conditional (rework then retest); PIM > -155 dBc = Fail and require retermination or replacement. Explanation: Documentation templates should capture sample ID, cable and connector part numbers, test conditions, measured results, and acceptance decision with signer and timestamp. Include a short remediation clause describing required actions for conditional or fail results. This standardization ensures consistent decisions across sites and simplifies procurement compliance checks.

5 — Comparative case studies: SPO-375 in real assemblies (Case study)

5.1: Typical assembly examples (SPO-375 + TC-375 with different connectors)

Point: Real-world assemblies illustrate how connector type and length influence both PIM and insertion loss. Evidence: Case A: SPO-375 with N-type soldered TC-375 for short DAS jumper—lab measurement showed PIM ≤ -165 dBc and insertion loss consistent with datasheet; Case B: SPO-375 with 7/16 crimped outdoor feeder at 30 m—PIM tests typically behaved ≤ -160 dBc when connector preparation and torque were controlled, with insertion loss matching expected per-meter tables. Explanation: For short jumpers in DAS (Case A), soldered N-type terminations yield very low connector contribution when executed correctly. For longer outdoor feeders (Case B), 7/16 DIN is a robust mechanical choice; pay attention to environmental sealing and clamp integrity. Present these case summaries with measured values and installation context so teams can map expected performance to their deployments.

5.2: Connector choice impact — measured differences and recommendations

Point: Connector selection and attachment method can introduce measurable differences in PIM sensitivity and insertion loss. Evidence: Comparative measurements show properly soldered connections frequently give the lowest PIM floor; crimp and clamp methods are comparable when executed per manufacturer processes but are more sensitive to operator variance. Explanation: Recommendations: use soldered attachments where lab-level PIM floors are required (short DAS jumpers), specify crimp/clamp with strict procedural controls for field feeders, enforce torque and cleanliness steps, and prefer connector designs with robust outer-conductor contact geometry. Document connector lot and installer ID to trace potential field issues back to processes or tooling.

5.3: Lessons from field deployments (common failure modes and fixes)

Point: Field deployments reveal recurrent failure modes—debris in mating surfaces, incomplete torque, cable damage at terminations, and inadequate strain relief. Evidence: Inspections commonly correlate elevated PIM with visible contamination or micro-gaps at the outer conductor mating surface and with over-bent cable near the connector body. Explanation: Practical fixes include enforcing connector cleaning immediately before mating, using calibrated torque tools, adding mechanical strain relief or protective boots, and training crews on minimum bend radius rules. For persistent issues, replace suspect connectors and retest; track field failure causes in a shared log to identify systemic tooling or material issues for procurement review.

6 — Practical recommendations & action checklist for RF teams (Action-oriented)

6.1: Pre-purchase spec checklist

Point: Procurement should use a compact checklist to ensure purchased parts meet project acceptance criteria. Evidence: Required checklist items include specified PIM threshold (e.g., ≤ -160 dBc at two-tone +43 dBm), maximum insertion loss per length at key frequency points, approved connector pairings, environmental and UV ratings, and required test documentation with serial-numbered assemblies. Explanation: Include contractual expectations for delivered sample test reports, calibration certificates for test equipment used in vendor qualification, and an initial production sample run (e.g., three assemblies) that the receiving lab will test to verify compliance before larger production acceptance.

6.2: Installation and test checklist (what to verify on site)

Point: On-site verification checklist helps installers ensure assembly performance at handover. Evidence: Checklist items: visual inspection, cleaning of mating surfaces, verify torque per connector spec, run PIM sweep using two-tone settings, perform insertion loss or VNA sweep, photograph terminations, and upload results to project repository. Explanation: Sequence tasks so that mechanical preparation (cleaning, torque) precedes electrical testing; if initial tests fail, follow documented remediation steps (re-clean, re-torque, replace connector) and re-test. Ensure all checks are logged with operator ID and timestamps for auditability and warranty support.

6.3: When to escalate to replacement vs. repair

Point: Decision rules avoid unnecessary replacements while ensuring network integrity. Evidence: Escalation thresholds: persistent PIM > -155 dBc after cleaning and re-torque → replace connector or cable section; insertion loss exceeding expected by more than tolerance margin and not corrected by re-termination → replace. Explanation: Use tiered actions: first-level remediation is cleaning and re-torque, second-level is re-termination (replacing the connector only), and third-level is replacing the cable assembly. Document the decision and retained failed samples for vendor failure analysis where warranty claims are needed.

Conclusion / Summary (10–15% of article)

In summary, SPO-375 is positioned as a low-PIM, low-loss 50 Ω solution when assemblies are made with controlled TC-375 connector attachments and tested per repeatable lab and field protocols. Key takeaways: require clear PIM and insertion loss specifications in purchase documents, implement the provided combined test protocol in both lab and field, and enforce installation practices—cleaning, correct torque, and strain relief—to maintain compliance and reduce field failures. Recommended next steps: run the standardized test protocol on three production samples and attach the completed results table to the procurement file for acceptance.

Key Summary

SPO-375 demonstrates low-PIM behavior when assembled per vendor guidance; require vendor PIM claims be validated with the provided two-tone test protocol before bulk acceptance.

Measure insertion loss at standard points (700 MHz, 850 MHz, 1.8 GHz, 2.4 GHz, 3 GHz) and include per-meter loss and tolerance in procurement specs for accurate link budgeting.

Field procedures—cleaning, correct torque, and strain relief—are critical to preserve low PIM and limit insertion loss variance across installations.

Adopt the pass/fail thresholds in reports: nominal pass ≤ -160 dBc, conditional rework zone -155 to -160 dBc, and fail > -155 dBc with prescribed remediation steps.

Frequently Asked Questions

H3: What are the typical PIM results for SPO-375 assemblies?

Measured PIM for properly prepared SPO-375 assemblies typically meets or exceeds vendor claims, with lab-verified results often at or below -160 dBc under two-tone +43 dBm test conditions. Field results can vary; follow cleaning and torque procedures, and if PIM exceeds -155 dBc after remediation, escalate to re-termination or replacement.

H3: How is insertion loss characterized for SPO-375 and what should I expect?

Insertion loss is reported per frequency and per length; expect low per-meter loss that increases with frequency due to skin effect. Use the provided table and graph templates to insert measured S21 data at 700 MHz, 850 MHz, 1.8 GHz, 2.4 GHz, and 3 GHz for 1 m, 10 m, and 100 m equivalents to support link-budget calculations.

H3: Which TC-375 connector attachments minimize PIM for SPO-375?

Soldered terminations generally provide the lowest and most consistent PIM floor when executed properly; crimp and clamp attachments can achieve acceptable results in the field if installation controls are enforced. Whichever method is used, enforce cleaning, correct solder practices or crimp tooling, and specified torques to minimize PIM risk.

H3: What should a field team do immediately if a PIM test fails on site?

Follow the troubleshooting flow: stop, inspect visually, clean mating surfaces, re-torque per spec, retest. If PIM remains high, swap or re-terminate the connector, retest the isolated segment, and record all steps. If failure persists, replace the assembly and preserve the failed sample for lab analysis and potential warranty claims.