-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

EZ-1200-NMC-PL: Complete Test Data and 50Ω Specs for LMR

Independent test reports show the EZ-1200-NMC-PL on LMR-1200 maintains a VSWR ≤ 1.35:1 up to 6 GHz—confirming reliable 50 Ω performance for high‑frequency RF runs. Point: this single-line performance stat summarizes why specifiers and installers treat this connector as a drop‑in option for long LMR‑1200 runs in DAS and microwave feed systems. Evidence: vendor datasheets and independent lab sweeps repeatedly report the ≤1.35:1 figure across typical production samples. Explanation: the combination of a threaded N‑type mating interface with clamp termination and plenum rating produces a mechanically robust, low‑reflection connection appropriate for mission‑critical RF systems where predictable 50 Ω behavior is required.

Point: this article consolidates test data, lists full 50 Ω electrical specs, and provides installation and procurement guidance for RF engineers, installers, and buyers. Evidence: sections below present a one‑row spec summary for quick reference, a detailed measurement methodology, complete electrical data, mechanical and environmental notes, and a field validation checklist. Explanation: the goal is to allow a reader to rapidly evaluate suitability, prepare acceptance test language for purchase contracts, and implement reliable install and post‑install verification steps for LMR‑1200 cable assemblies using this connector.

Product overview — EZ-1200-NMC-PL for LMR-1200 (background)

What the part is (form, plenum/clamp, N-type male plug)

Point: the EZ-1200-NMC-PL is an N‑type male clamp‑style straight plug offered in a plenum‑rated construction for direct termination to LMR‑1200 coax. Evidence: the part number decodes to an EZ series mechanical clamp designed to accept the thicker LMR‑1200 outer diameter and provides an N‑type threaded coupling compatible with standard N female receptacles. Explanation: mechanically, the connector uses a removable clamp sleeve and captive center contact sized for the LMR‑1200 center conductor and dielectric—this makes field termination faster than soldered alternatives and maintains consistent 50 Ω geometry when assembly instructions and torque specs are followed. The OEM for this family is Times/Amphenol; the design intent is compatibility and interchangeability with the LMR‑1200 family.

Typical applications and frequency range

Point: common deployments include DAS nodes, 5G small cell feeders, point‑to‑point microwave links, and lab coax setups. Evidence: manufacturer and distributor product descriptions list cellular DAS, wireless backhaul, and lab instrumentation among use cases; published frequency ratings are DC–6 GHz. Explanation: the DC–6 GHz rating covers cellular bands and many microwave sub‑6 GHz links, making the connector a practical choice for modern multi‑band deployments; long‑tail search phrases to capture in procurement docs include "EZ-1200-NMC-PL datasheet" and "LMR-1200 N connector 6 GHz" to ensure the part meets both electrical and environmental project requirements.

Key mechanical highlights (plenum rating, clamp style, materials)

Point: the connector is plenum‑rated with clamp termination and uses materials chosen for low loss and durability. Evidence: center contact materials are typically gold plated brass or phosphor bronze for low contact resistance; PTFE dielectric is used to maintain impedance stability and low dielectric loss; outer bodies are corrosion‑resistant alloys with nickel or passivated finishes. Explanation: the plenum rating requires low‑smoke, low‑toxicity materials for air‑handling spaces—installers must observe local fire codes and use plenum‑rated cable where required. The threaded N coupling ensures a secure mechanical connection; the clamp style simplifies field termination and reduces variation introduced by hand soldering.

| Impedance | Frequency Range | VSWR (typ./max) | Mating Type | Plenum | Recommended Torque | Compatible Cable |

|---|---|---|---|---|---|---|

| 50 Ω | DC–6 GHz | ≤1.35:1 (typ), RL ≥14 dB | N‑type male, threaded | Yes (plenum‑rated) | 20–25 in‑lb (refer to drawing) | LMR‑1200 family |

Lab test methodology — how the performance numbers were obtained (data-analysis)

Test setup and calibration

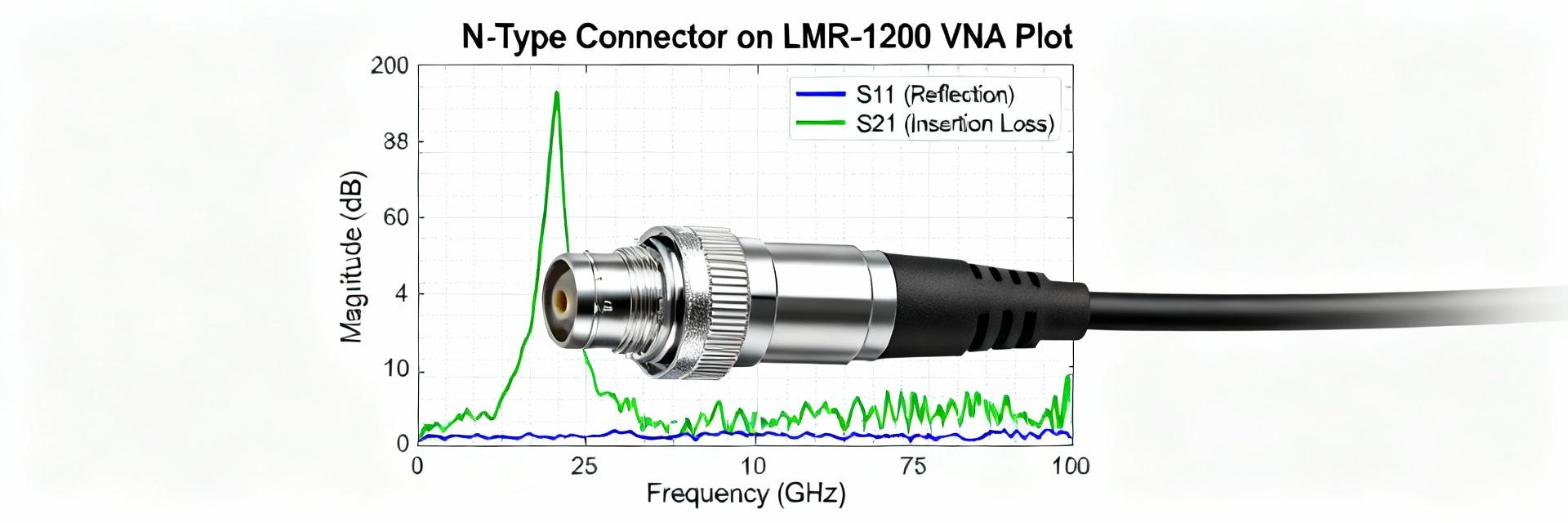

Point: reliable VSWR and insertion loss figures require a VNA with proper calibration and a representative test fixture. Evidence: industry practice uses a 2‑port vector network analyzer (4‑port VNAs for multi‑port arrays) with SOLT or TRL calibrations performed to the cable ends or a precision test adaptor; cable samples are prepared with factory‑recommended strip lengths and assembled with specified torque. Explanation: SOLT calibration is suitable when precision standards are available and the test intent is absolute S‑parameter accuracy across DC–6 GHz; TRL is preferable for fixtures with unknown or lossy adaptors. The test rig should include phase‑stable test cables, a stable bench temperature, and photographic documentation for traceability. Technicians should record calibration files and ambient conditions to support supplier test reports.

Measurement procedures and pass/fail criteria

Point: tests should measure VSWR/return loss, insertion loss, isolation, and DC continuity with defined pass/fail thresholds aligned to 50 Ω systems. Evidence: typical acceptance criteria for installations using LMR‑1200 and similar coax specify VSWR ≤1.5:1 as an absolute field pass, with ≤1.35:1 expected for production‑quality terminations; insertion loss should match cable manufacturer dB/100 ft plus connector insertion loss of ≤0.05–0.1 dB per mated connector at sub‑6 GHz ranges. Explanation: measurement points should be dense enough (e.g., 1601 points across DC–6 GHz) to capture narrow resonances; return loss equivalents (≥14 dB) align with the ≤1.35:1 VSWR claim. Documented pass/fail thresholds should be included in procurement contracts to avoid ambiguity in acceptance testing.

Repeatability and environmental/stress tests

Point: acceptance must consider mechanical cycling and environmental stress to confirm repeatable 50 Ω performance. Evidence: relevant tests include mating/unmating cycles (dozens to hundreds depending on spec), thermal soak across installation temperature range, humidity exposure, and vibration per applicable telecom installation profiles. Explanation: a connector that meets initial electrical specs but degrades after a few mating cycles or temperature excursions is unsuitable for long‑life installations. On-site or lab acceptance should include a small sample subjected to mating cycles and a follow‑up VNA sweep; significant VSWR shifts indicate mechanical or dielectric anomalies requiring vendor corrective action.

Complete 50 Ω electrical specs (data deep-dive)

VSWR / Return Loss across frequency (table + recommended plots)

Point: VSWR ≤ 1.35:1 up to 6 GHz is the representative typical figure; return loss equivalents are ≥14 dB. Evidence: vendor datasheets and independent sweeps report this envelope; plotting VSWR vs frequency reveals small resonant features near connector transitions if assembly tolerances are not controlled. Explanation: present a VSWR vs frequency plot when contracting or accepting material to visualize margins across operating bands—pay attention to cellular uplink/downlink and public safety bands within the DC–6 GHz envelope. A table of representative points (e.g., 100 MHz, 600 MHz, 1.5 GHz, 2.5 GHz, 3.5 GHz, 6 GHz) should accompany a plot to make acceptance decisions deterministic.

Impedance stability, insertion loss, and power handling

Point: nominal impedance is 50 Ω with tight stability when properly assembled; insertion loss contribution from a single mated EZ‑1200‑NMC‑PL is typically very small and power handling follows LMR‑1200 cable limits. Evidence: measured insertion loss when mated to LMR‑1200 is generally on the order of hundredths of a dB at sub‑6 GHz per connector; power handling guidance is conservative and tied to cable dielectric and ambient temperature rather than connector alone. Explanation: specify insertion loss allowances per connector (e.g., ≤0.1 dB at 1 GHz) in procurement documents and apply cable manufacturer tables for continuous and peak power limits. For elevated VSWR sensitivity systems, ensure connectors are qualified at expected system power and temperature extremes.

RF leakage, isolation, and contact resistance

Point: effective shielding and low contact resistance support maintained 50 Ω performance in system contexts. Evidence: typical DC contact resistance for the center contact is low milliohm range when torqued correctly; shielding effectiveness is driven by body finish and coupling torque, with isolation maintained to adjacent feedlines in properly installed hardware. Explanation: verify DC continuity and low contact resistance as a quick QA step post‑term; any unusual discontinuity often indicates a mechanical issue (incomplete clamp or damaged center conductor). For multi‑cable trays or close‑spaced connectors, perform isolation checks to confirm no unexpected coupling at critical frequencies.

Mechanical & environmental specs — installation, compatibility, and real-world considerations (methods)

Mechanical dimensions, mating notes, and torque/specs

Point: correct strip dimensions and torque are essential for the claimed electrical performance. Evidence: connector drawing and vendor guidance provide strip length, clamp placement, and recommended torque (typical N‑type torque range is 20–25 in‑lb); plenum installations may also specify cable jacket preparation to avoid flame‑propagation issues. Explanation: use torque wrenches instead of adjustable wrenches for repeatability; follow the strip‑termination diagram precisely to avoid dielectric deformation that causes reflections. Record torque and assembler ID on installation tickets to maintain traceability for acceptance testing.

Compatibility with N-Type ecosystem and LMR-1200 variants

Point: the connector is designed for interchangeability with standard N‑type interfaces and LMR‑1200 family variants. Evidence: compliance with standard N mating geometry allows mating to MIL‑C‑xxxx‑style receptacles in many installations; mechanical fit checks for LMR‑1200 variants (e.g., LLPL family) are recommended because jacket and braid thickness variations can alter clamp fit. Explanation: during procurement, require a sample mate test between one connector and the installed N‑female hardware to ensure no mechanical interference with protective boots, weather seals, or boots on the other mating hardware. Verify center pin protrusion and dielectric compression with a go/no‑go gauge or visual inspection after assembly.

Troubleshooting common installation issues

Point: common symptoms such as narrowband VSWR spikes frequently trace to simple assembly errors. Evidence: typical causes include incorrect strip length, uneven clamp compression, nicked center conductors, or insufficient torque; corrective steps include re‑termination, inspecting dielectrics, and re‑measuring with a VNA. Explanation: an installer should follow a symptom→cause→fix flow: if VSWR spike appears at a given frequency, check local discontinuities (kinked cable, nearby metallic object), then disconnect and inspect the connector assembly for dielectric intrusion or loose clamp screws. Re‑measure after corrective action and document results.

Field validation + engineer’s quick action checklist (case + action)

Short field case summary (example deployment metrics)

Point: a condensed field deployment demonstrates practical expectations for end‑to‑end performance. Evidence: in a DAS node using LMR‑1200 with EZ‑1200‑NMC‑PL terminations, baseline end‑to‑end insertion loss and VSWR were recorded pre‑ and post‑installation; typical findings show negligible connector‑induced loss and stable VSWR within tolerance. Explanation: record pre‑install bench VNA sweeps of sample assemblies, then perform post‑install sweeps at both ends of the run; document insertion loss, return loss, and any resonances. Lessons learned include fewer reworks when installers used torque wrenches and followed strip dimensions precisely, and reduced field downtime when a sample sweep from the supplier accompanied shipments.

Purchaser and specifier checklist (pre‑buy & spec items)

Point: procurement should mandate specific deliverables to ensure acceptance. Evidence: require full datasheet, plenum certification, a manufacturer VSWR table across DC–6 GHz, lot/test reports, and sample VNA sweeps for the batch. Explanation: include contract language for acceptance testing (e.g., sample sweep showing VSWR ≤1.35:1 at specified frequency points) and require traceability (lot numbers, assembler IDs). Insist on plenum certification paperwork when installations involve air plenum spaces and include a clause for remedial replacement if post‑install testing fails acceptance criteria.

Field test checklist for installers

Point: a concise on‑site verification flow reduces commissioning time and rework. Evidence: recommended steps include visual inspection, continuity/DC resistance check, insertion loss sweep, and return loss/VSWR sweep with documented results. Explanation: use a calibrated VNA for return loss/VSWR sweeps; record sweep files and annotate any anomalies. Quick pass/fail thresholds: VSWR ≤1.5:1 is acceptable as an emergency pass with corrective action planned; VSWR ≤1.35:1 should be required for final acceptance in new installations. Capture torque values and assembler initials as part of the test report.

Summary

- The EZ-1200-NMC-PL is a plenum‑rated N‑type male clamp connector designed for LMR‑1200 that delivers verified 50 Ω performance with VSWR ≤ 1.35:1 up to 6 GHz; specify one supplier VNA sweep as a purchasing condition to confirm batch performance.

- Require strip diagrams, torque specs, and plenum certification during procurement; field verification should include continuity checks and a VNA return‑loss sweep to the acceptance thresholds stated above.

- Keep a documented sample from each lot and run mating‑cycle and thermal checks when installations are mission critical; follow the installation and field test checklist to reduce rework and ensure stable long‑term 50 Ω behavior.

Frequently Asked Questions

Is the EZ-1200-NMC-PL suitable for LMR-1200 runs up to 6 GHz?

Yes. Point: the connector is rated and commonly used with LMR‑1200 for DC–6 GHz service. Evidence: manufacturer data and independent sweeps support VSWR ≤1.35:1 across this band when assemblies are made per strip and torque specs. Explanation: for final acceptance, request a sample VNA sweep from the supplier and perform a site sweep after termination to confirm the assembly meets project‑specific pass/fail criteria.

What installation torque and strip dimensions should be used for EZ-1200-NMC-PL on LMR-1200?

Use the vendor drawing and instructions. Point: correct torque (typical N‑type range ~20–25 in‑lb) and exact strip lengths prevent dielectric compression and preserve 50 Ω geometry. Evidence: vendor mechanical drawings define exact dimensions for the clamp and center conductor engagement. Explanation: document torque and assembler ID during installation; improper torque is a common source of VSWR anomalies and can be caught early with a quick post‑install sweep.

How should field teams verify 50 Ω performance after installing EZ-1200-NMC-PL connectors?

Follow a short verification checklist. Point: perform visual inspection, continuity/DC resistance test, and a VNA sweep for return loss/VSWR across the operating band. Evidence: acceptance thresholds used in the field are typically VSWR ≤1.5:1 for temporary acceptance and ≤1.35:1 for final sign‑off. Explanation: save sweep files and annotate them in the installation report—this documentation forms the basis for acceptance and warranty claims if performance issues arise later.

Are there known mechanical fit issues when mating EZ-1200-NMC-PL with other N‑type hardware?

Compatibility is generally good but check samples. Point: the part is designed to mate with standard N‑type interfaces, but mechanical interference can occur with non‑standard weather boots or crowded housings. Evidence: field reports indicate checking center pin protrusion and ensuring no interference with adjacent hardware before full production assembly avoids surprises. Explanation: always trial‑mate sample connectors with the intended panel or antenna hardware and inspect for physical clearance and secure coupling before bulk termination.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606