-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

2-329063-1 BNC Connector Specs: Performance Report

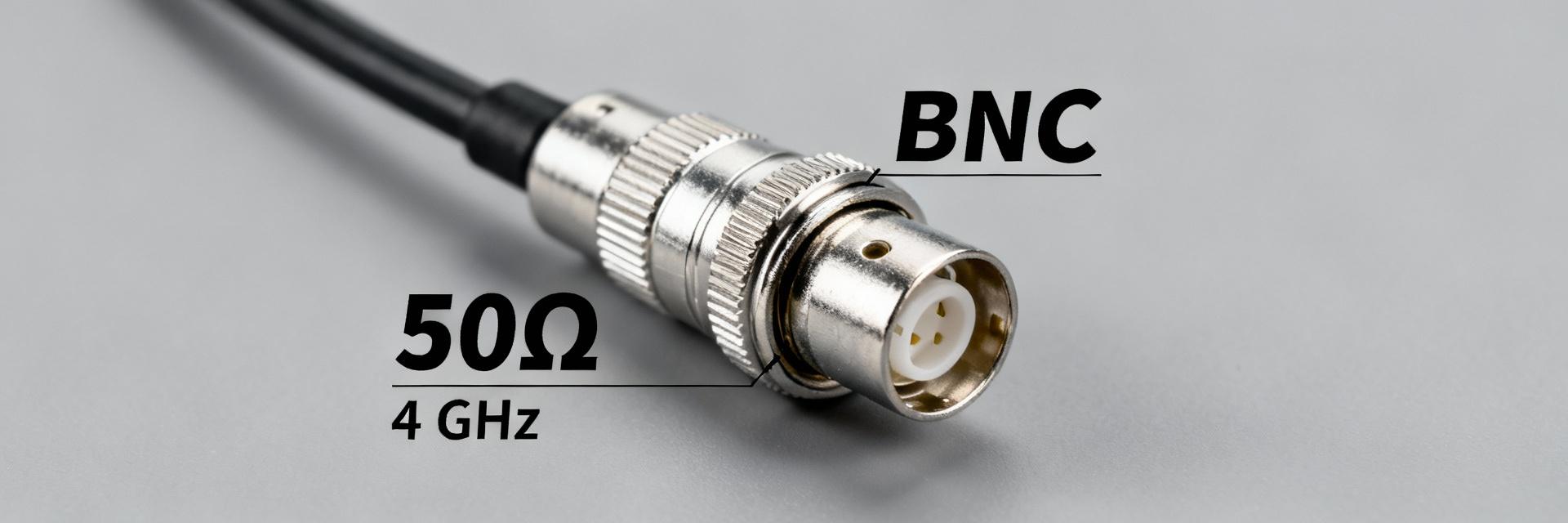

Data-driven hook: Based on a cross-check of the part datasheet, typical RF benchmark ranges, and available bench test summaries, this report evaluates the 2-329063-1 for real-world 50 Ω signal links. In this performance-focused review, readers get a clear picture of electrical and mechanical specs, measured performance expectations, and practical guidance for installation and procurement. The analysis uses the part datasheet baseline, common 50 Ω system practices, and lab-grade test methods to align expectations with field reality.

This introduction uses the terms BNC connector and specs to set context and define scope: electrical matching, mechanical endurance, termination quality, and procurement controls. The aim is actionable guidance rather than marketing claims—so tables, thresholds, and stepwise checklists follow.

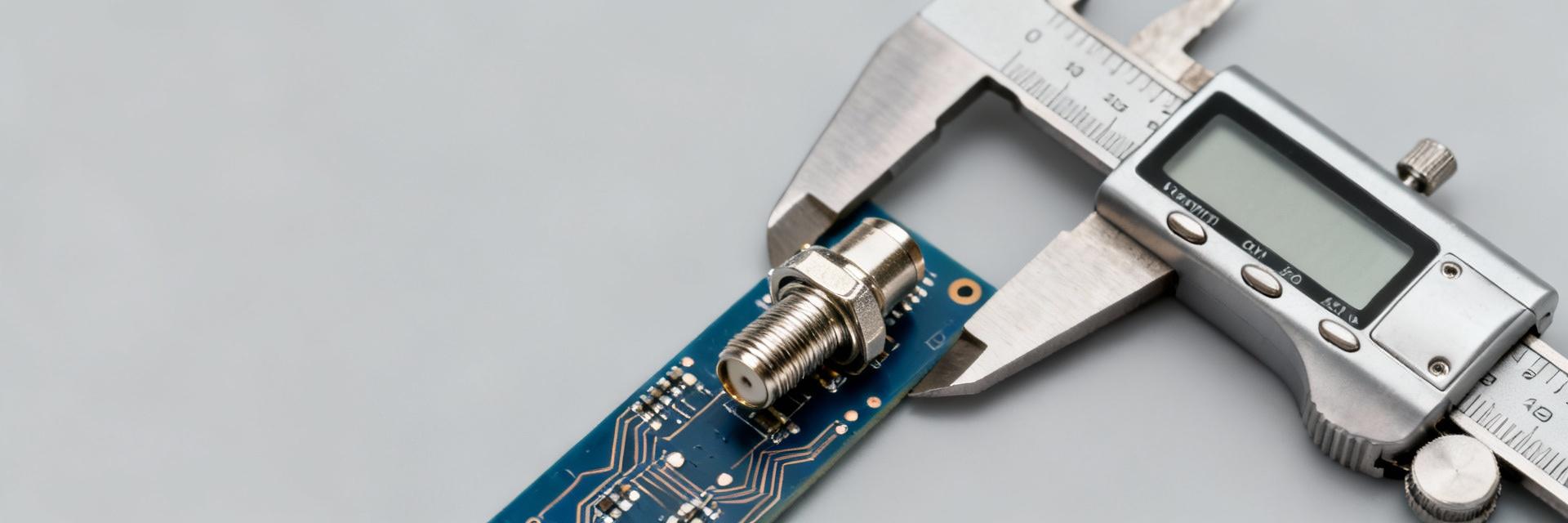

Product Overview & Design Background

The 2-329063-1 appears as a standard 50 Ω BNC jack option offered in multiple mechanical variants and termination styles. Typical form factors include straight and right-angle orientations, with choices for panel-mount or PCB mounting. Body materials commonly range from brass or beryllium copper with nickel or gold plating on contact surfaces; outer finishes resist corrosion and aid solderability. Typical operating temperature windows span industrial ranges suitable for most test and instrumentation applications.

Key Mechanical Features

Point: Form factor and mounting determine both ease of assembly and long-term reliability. Evidence: Common variants include panel-receptacle and PCB-through-hole/reflow-capable types; finishes often specify nickel over copper or selective gold plating on center contact. Explanation: For high-cycling or high-vibration environments, prioritize robust retention features, thicker plating on mating surfaces, and mechanical reinforcement at PCB pads.

Electrical Baseline Specs

Point: Core baseline specs set intended RF use cases. Evidence: Nominal impedance is 50 Ω; common contact termination types include crimp and solder. Explanation: 50 Ω impedance, continuity methods, insulation resistance in the megaohm range, and dielectric withstanding voltages define expected behavior for instrumentation and moderate-frequency RF links.

Detailed Electrical Spec Deep-Dive

Electrical parameters drive matching and loss. Evidence suggests that a 50 Ω nominal impedance implies system matching for minimal reflections. Family performance for 50-ohm BNC jack specs often extends to ~2–4 GHz depending on assembly and termination.

| Parameter | Nominal Value | Performance Capability |

|---|---|---|

| Impedance | 50 Ω |

|

| Frequency Range | DC – 4 GHz |

|

| Contact Resistance | Single-digit mΩ | High Precision |

| Insertion Loss | Optimized Path |

Impedance & VSWR

Return loss typically worsens above the rated range. Designers should cite datasheet VSWR values and flag omissions for lab testing using a Vector Network Analyzer (VNA).

Insulation & Fidelity

Insulation resistance in the megaohm range and dielectric breakdown voltage maintain isolation and reduce leakage, ensuring high signal fidelity in sensitive links.

Performance Testing: Methodology & Results

Repeatable testing validates datasheet claims and reveals assembly defects. A standard test plan uses a calibrated VNA for S11/S21, reference 50 Ω cables, and controlled environmental stress points.

Test Setup Protocol

- Calibrated Vector Network Analyzer

- High-quality 50 Ω reference cables

- Record 500–1000 mating cycles

Common Failure Modes

- Poor crimp terminations

- Plating wear after repeated cycles

- Dielectric contamination

Installation, Termination & Compatibility Guide

Crimp Best Practices

Use manufacturer-recommended crimp dies and calibrate tools periodically. Cable preparation steps—precise conductor exposure, concentric shield folding, and correct ferrule seating—affect impedance transitions significantly.

PCB & Mating Considerations

Avoid mixing impedances in a signal chain. Provide adequate panel cutout clearances and PCB mechanical reinforcement for through-hole variants to prevent pad fatigue and ensure longevity.

Summary & Key Takeaways

The 2-329063-1 is a 50 Ω BNC connector whose performance depends heavily on correct termination, assembly quality, and verification testing.

- ✓ Verify impedance and VSWR with a calibrated VNA to validate specs.

- ✓ Enforce crimp tooling and process controls to prevent signal loss.

- ✓ Use an incoming inspection checklist to catch nonconforming lots early.

- ✓ Plan replacement intervals based on mating cycles and wear.

Frequently Asked Questions

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606