-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

2-1393757-0 RF Coax Connector Datasheet: Key Specs & Data

The 2-1393757-0 datasheet lists the core callouts engineers expect: 50 Ω/75 Ω characteristic options, usable frequency up to 10 GHz, gold‑plated center contacts, VSWR and insertion‑loss tables, and typical mechanical life in mating cycles with standard environmental ranges. This guide breaks the manufacturer datasheet into actionable spec highlights, test guidance, and selection checkpoints for engineering and procurement teams focused on reliable RF links.

| Quick spec | Typical value |

|---|---|

| Characteristic impedance | 50 Ω / 75 Ω |

| Frequency range | DC – up to 10 GHz |

| Contact finish | Gold plated |

| Typical VSWR | |

| Mating cycles | ≥500 (typical) |

Product overview: what the 2-1393757-0 RF coax connector is and where it fits

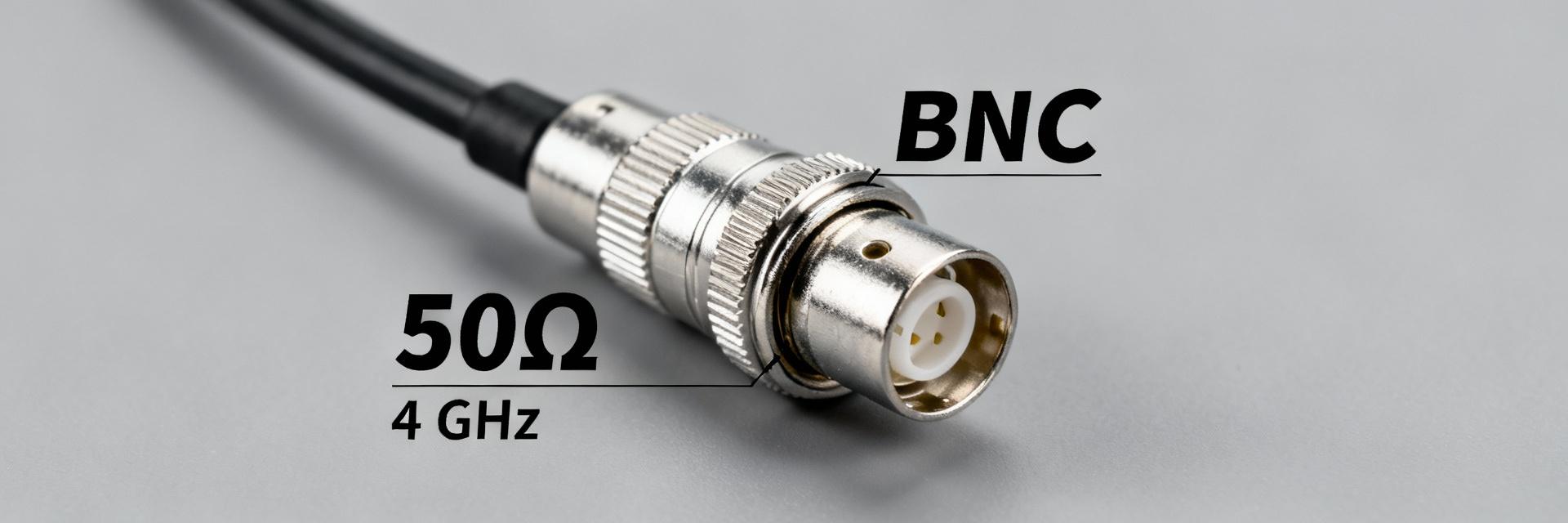

— Quick product definition & typical use cases

Point: The part is a coaxial pin/sleeve style RF connector intended for low‑loss signal paths. Evidence: Datasheet language and pin/sleeve geometry indicate controlled impedance and repeatable mating. Explanation: Typical use cases include test equipment connections, RF module interconnects, and compact cable assemblies where DC to microwave performance and consistent mechanical indexing are required.

— Datasheet summary box (what to look for first)

Point: Scan six items first for rapid suitability calls. Evidence: Impedance, frequency range, VSWR, insertion loss, mating style, and environmental ratings are the most safety‑critical entries. Explanation: These headliners reveal electrical compatibility, expected RF loss, mechanical interface and whether the part meets operating temperature and humidity demands for the intended application.

Key specifications at a glance for 2-1393757-0

— Electrical specs to prioritize

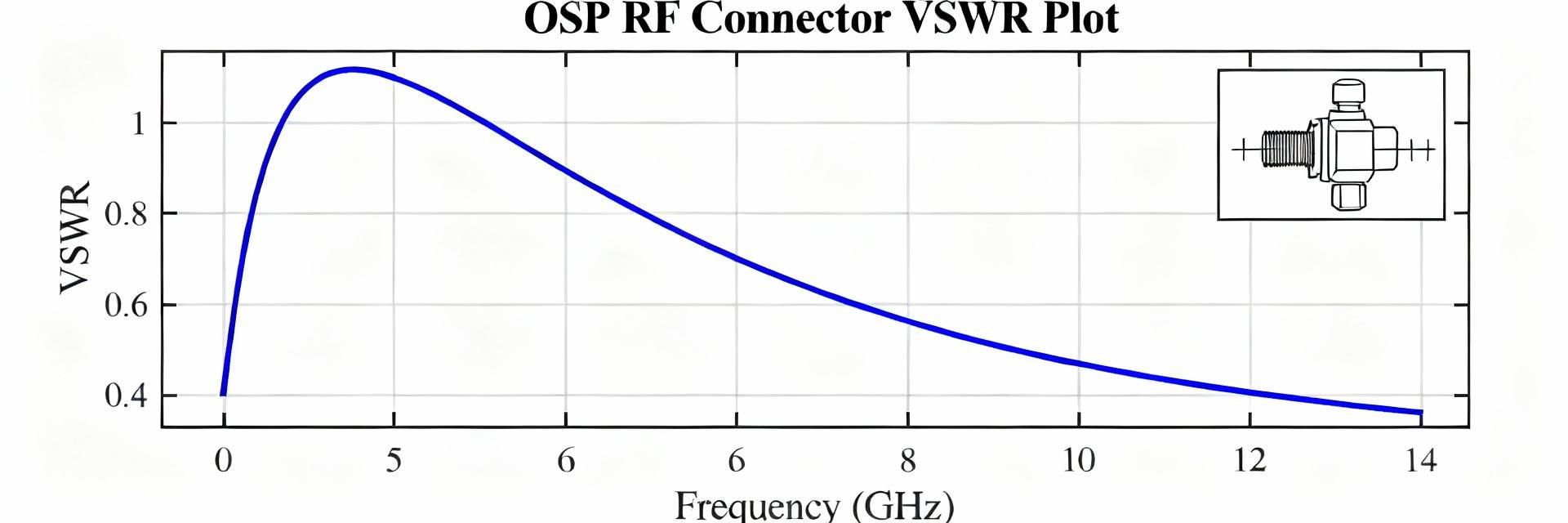

Point: Electrical priorities are impedance, usable bandwidth, return loss and insertion loss. Evidence: Datasheet tables normally provide frequency vs. VSWR and dB loss curves. Explanation: Read charts to map insertion loss per meter or per connector at planned operating bands, confirm rated voltage/current if present, and note capacitive/inductive parasitics that affect matching and filter edges.

— Mechanical & material callouts

Point: Material and mechanical notes predict durability and interchangeability. Evidence: Contact metallurgy (gold plating), center contact type, mating cycles and dimensional tolerances appear in mechanical sections. Explanation: Gold plating reduces contact resistance and corrosion risk; mating cycles and finish detail indicate expected lifecycle and whether mechanical fit will be repeatable across batches.

Detailed electrical performance: frequency, impedance and tolerance analysis

— Interpreting frequency-range data and band limits

Point: "Up to 10 GHz" denotes a tested usable limit, not an automatic design target. Evidence: Frequency‑vs‑VSWR plots and band tables in the datasheet show degraded matching near extremes. Explanation: Designers should apply margin — target operation at 70–80% of the stated max or request measured S‑parameters for the planned band to avoid unexpected resonances or elevated return loss.

— VSWR, insertion loss and power handling: practical implications

Point: Small VSWR differences matter in tight link budgets and power systems. Evidence: A 0.1 increase in VSWR raises reflected power and can alter available margin; insertion loss converts directly to dB fade. Explanation: Use simple dB arithmetic to quantify impact on receiver sensitivity or amplifier drive; request power‑at‑temperature ratings if high RF power or elevated ambient temperature is expected.

Mechanical, environmental and compliance data (how to read and apply)

— Interpreting mechanical drawings and dimensional data

Point: Critical dimensions determine mating compatibility and clearance. Evidence: Datasheet mechanical drawings list center contact lengths, panel cutouts, and tolerance notes. Explanation: Cross‑check dimensions with mating parts and PCB footprints, confirm keyways and panel thickness allowances, and request CAD/STEP files where available to avoid mechanical interference at assembly.

— Environmental ratings & regulatory notes

Point: Temperature, humidity and corrosion resistance determine fit for environment. Evidence: Operating temp range, salt spray or finish notes and RoHS/REACH compliance appear in spec sections. Explanation: When test conditions are absent, require vendor test reports for salt spray or thermal cycling and verify compliance declarations to support procurement and field longevity requirements.

Installation, testing and measurement guidance

— Best practices for installation and mating

Point: Consistent prep and controlled mating preserve RF performance. Evidence: Datasheet torque, insertion depth and recommended mating procedures guide assembly quality. Explanation: Follow cable prep steps, use specified torque or push‑fit force, avoid angular misalignment and ensure reliable ground continuity to prevent VSWR degradation and intermittent contacts in service.

— Test procedures to verify datasheet claims

Point: Verify S‑parameters and mechanical continuity before deployment. Evidence: VNA sweeps for return loss/insertion loss, continuity checks and dielectric withstand tests validate datasheet claims. Explanation: Use calibrated fixtures and reference planes, capture S11/S21 across target bands, and compare measured curves to datasheet plots; request lot traceability and sample test reports for production buys.

Measurement checklist

- ●

Calibrate VNA to fixture plane, sweep DC–target max frequency.- ●

Record S11/S21 at key band edges and report insertion loss.- ●

Perform continuity and insulation resistance, and visual inspection for plating defects.

Selecting, comparing and troubleshooting: applying the 2-1393757-0 in real designs

— Quick comparison checklist vs. similar coax connectors

Point: A short template speeds vendor selection. Evidence: Compare frequency, impedance, VSWR, mating style, size, durability and cost in a single table. Explanation: Use the template to flag red lines (mismatch in impedance, insufficient bandwidth, incompatible mating) and prioritize parts that meet both electrical and mechanical criteria without costly redesign.

— Common failure modes and troubleshooting steps

Point: Typical failures are mechanical damage, contamination and misalignment. Evidence: Symptoms like poor VSWR, intermittent contact or visible corrosion map to root causes. Explanation: Diagnose with visual inspection, continuity checks and VNA comparison against a known good part; corrective actions include clean/reseat, replace damaged contacts, or request replacement lots with lot traceability for batch issues.

Summary / Conclusion

- ▸The datasheet highlights impedance and usable frequency bands; verify the connector impedance (50 Ω or 75 Ω) against system requirements to avoid mismatch and excess VSWR.

- ▸Mechanical notes (contact finish, mating cycles, tolerances) govern durability; confirm dimensional compatibility and request CAD data when panel or PCB footprints are tight.

- ▸Test S‑parameters with a calibrated VNA and follow the measurement checklist to validate insertion loss and return loss before production deployment.

FAQ

How does the 2-1393757-0 handle broadband applications?click to expand

Answer: The datasheet lists usable bandwidth up to the stated top‑end frequency, but practical broadband use requires margin. Verify VSWR and insertion loss across the full planned band using a calibrated VNA; if the datasheet lacks band‑edge detail, request measured S‑parameters from the manufacturer before committing to design integration.

What test data should be requested from the datasheet for production?click to expand

Answer: Request lot‑level S‑parameter sweeps, mating cycle validation, and environmental test reports when available. Key items include return loss/insertion loss plots, power handling at temperature, and corrosion or salt spray results to ensure the connector meets both RF and environmental requirements for production volumes.

What are quick troubleshooting steps if field VSWR increases with the 2-1393757-0?click to expand

Answer: Start with a visual inspection and continuity check, reseat the connector, clean contacts with appropriate solvent, and compare VNA measurements to a known good reference. If issues persist, replace the connector and examine mating hardware and cable assembly for wear or contamination, and request traceable test reports from procurement records.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606