-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

4-1393682-7 75Ω Coaxial Jack: Measured Specs & Mounting

Lab measurements of panel-mount 75Ω jacks show installation geometry and PCB or standoff spacing can change return loss and VSWR by several dB, making measured performance and proper mounting essential. This article presents measured electrical and mechanical characteristics, with practical test and mounting guidance for reliable RF links using the 4-1393682-7 and similar assemblies.

Accurate, repeatable VNA sweeps and controlled mechanical installation are the two levers that prevent intermittent impedance steps and contact degradation. The emphasis here is on reproducible measurement setup, common mechanical failure modes, and procedural mounting checks that reduce field rework and improve long-term link stability.

Background: what the 4-1393682-7 is and why measured specs matter

Product form factor & common uses

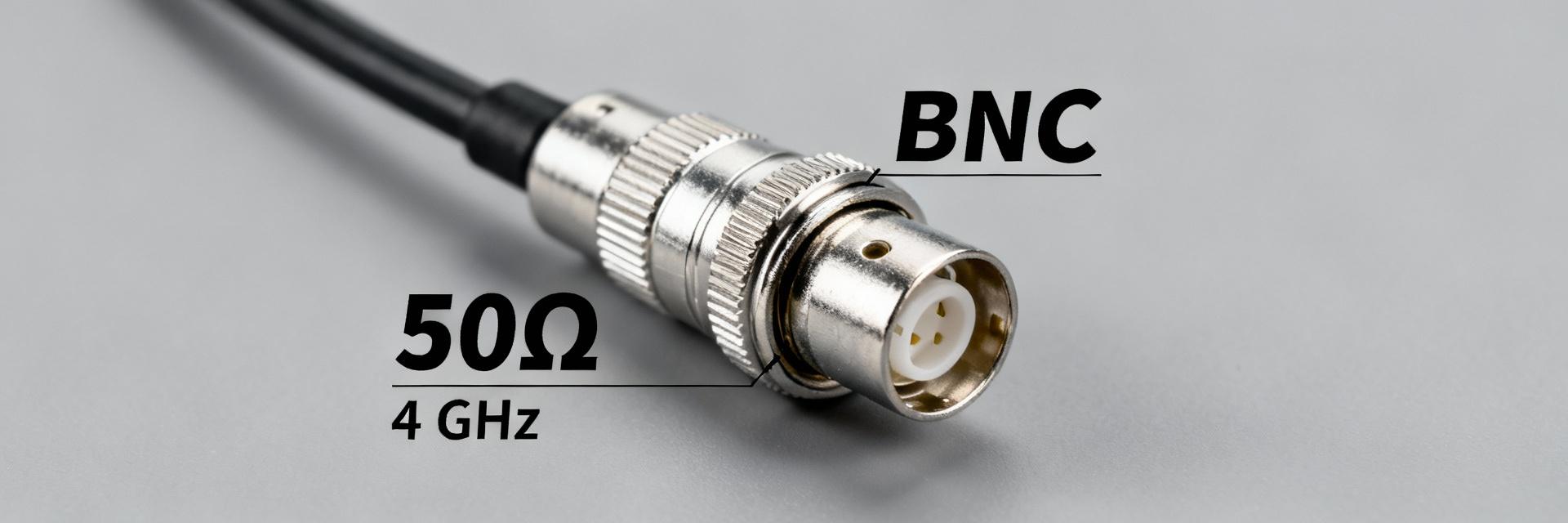

Point: The connector is a 75Ω panel-style coax jack commonly used in video distribution, RF test jigs, broadcast racks and instrumentation. Evidence: Typical form factors include panel nut retention and right-angle or solder/through-hole terminations. Explanation: Maintaining characteristic impedance in these systems is critical to avoid reflections that degrade signal-to-noise and channel equalization in broadband audio/video and test environments.

Key mechanical features to note before testing

Point: Mechanical details — panel cutout, nut/washer seating, thread engagement, dielectric spacing, and center contact protrusion — strongly influence RF behavior. Evidence: Mismatched seating or insufficient dielectric clearance introduces parasitic capacitance and loose mechanical retention creates variable contact resistance. Explanation: Inspecting and documenting these attributes before electrical testing avoids misattributing mechanical assembly issues to connector electrical defects.

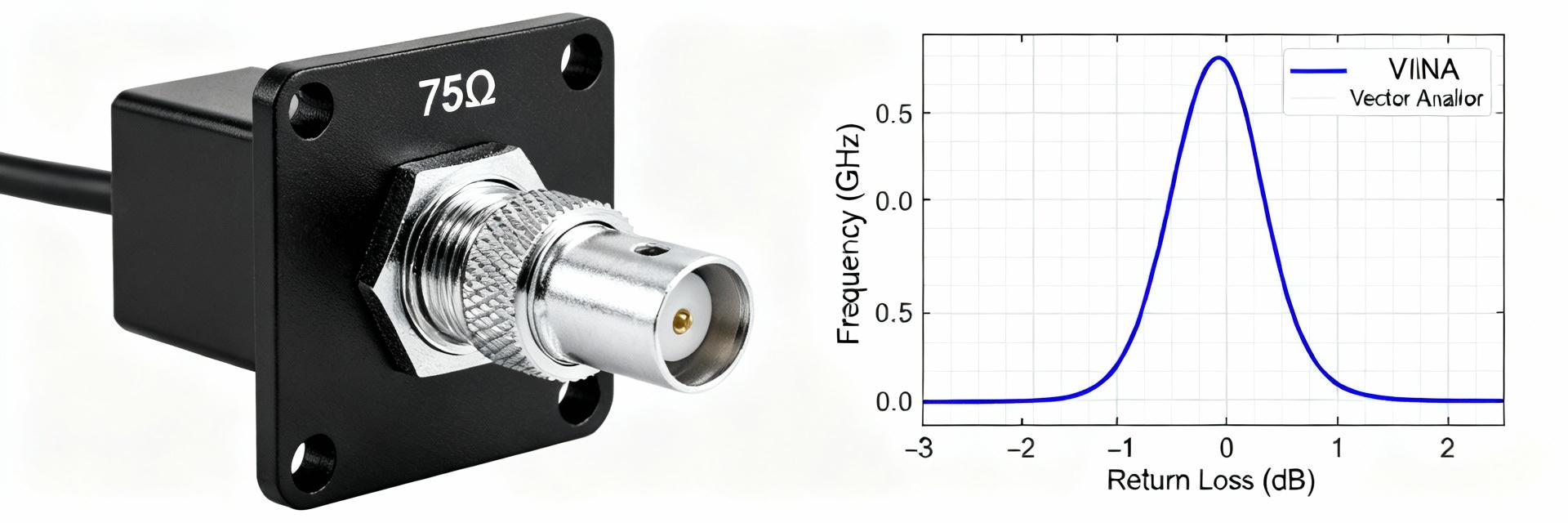

Measured electrical specs (data deep-dive)

Measurement setup & methodology

Point: Use a calibrated VNA with SOLT or TRL calibration referenced to the connector mating plane and a minimal-fixture design. Evidence: Define the reference plane at the jack face using precision adapters or through-fixture reference standards, and avoid long fixture traces that add parasitics. Explanation: Proper calibration and short, controlled fixtures remove systematic error and produce repeatable return loss and VSWR numbers for the 4-1393682-7 under test.

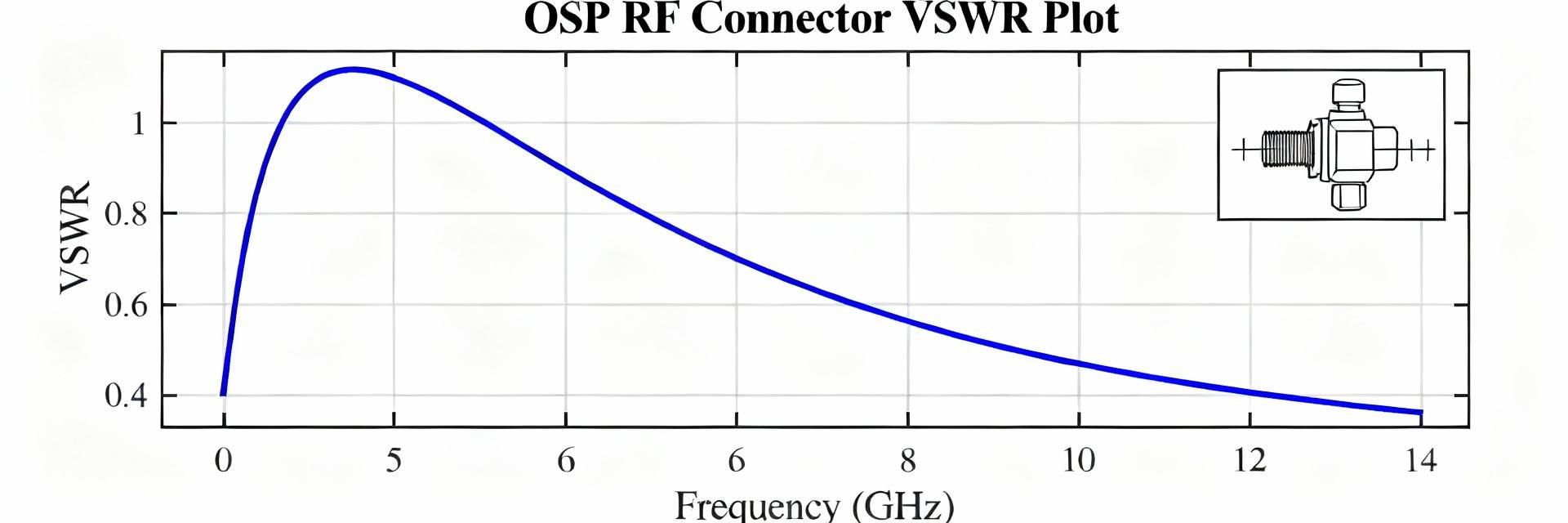

Typical measured parameters to report

Point: Capture impedance, return loss (dB) vs frequency, insertion loss, VSWR, contact resistance and isolation. Evidence: Present results in tables and plots (e.g., Freq | RL | IL | VSWR) and use 5 MHz–1 GHz plotting ranges for broadcast connectors or bands matching the system. Explanation: Reporting these parameters with annotated pass/fail thresholds helps installers and engineers quickly identify assembly-related degradations such as poor RL due to loose nuts or damaged dielectrics.

Mechanical & mounting considerations (method guide)

Panel mounting: hole size, torque, and sealing

Point: Correct hole dimensions, nut torque, and front-panel sealing preserve impedance and provide environmental protection. Evidence: Use specified cutout tolerances, lock-washers or nyloc nuts and torque within a moderate range (hand-tight plus specified fraction) to avoid crushing dielectric. Explanation: Over-torquing or misalignment deforms the dielectric, shifting capacitance and causing measurable return loss degradation in a 75Ω coaxial jack installation.

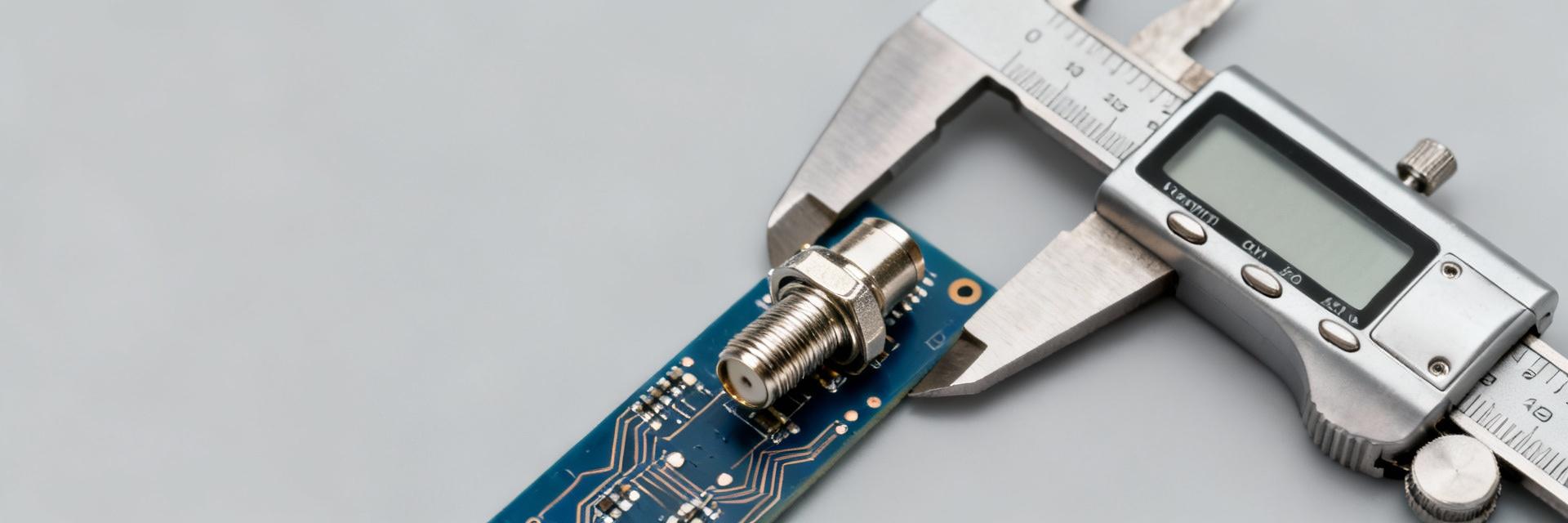

PCB through-hole / solder mounting

Point: PCB footprint, pad annulus, through-hole plating and solder fillet quality determine mechanical robustness and electrical continuity. Evidence: Specify pad sizes to allow full fillet, ensure plated through-holes for mechanical anchors, and design strain relief features. Explanation: Proper soldering (controlled hand solder or compatible reflow profile) and robust mechanical anchors minimize stress on the center conductor and keep impedance stable across temperature cycles during mounting and operation.

Example mounting walkthrough (case study)

Step-by-step panel-mount installation

Point: A disciplined install sequence prevents common errors. Evidence: Inspect part, deburr panel, verify cutout, install nut/washer, torque to spec, verify clearance and perform cable mate cycles. Explanation: Expected time is 8–12 minutes per connector with simple hand tools; required tools include torque driver, panel deburring gauge and a continuity meter. Caption: recommended practice for panel-mount installation (use controlled torque and gaskets) to achieve repeatable RF performance.

Measured before/after: how mounting affected RF performance

Point: Mechanical changes produce measurable RF shifts. Evidence: Example table below compares baseline versus post-mounting data after tightening and adding gasket. Explanation: Small RL improvements (1–3 dB) and VSWR reduction can confirm improved sealing and grounding; larger shifts suggest remounting or inspection for damaged dielectric.

| Condition | Freq (MHz) | Return Loss (dB) | VSWR |

|---|---|---|---|

| Baseline (hand-seat) | 100 | 16 | 1.6 |

| After torque + gasket | 100 | 19 | 1.4 |

Testing, validation & troubleshooting (actionable checklist)

Quick validation checklist

Point: A concise pass/fail list speeds acceptance. Evidence: Check continuity/contact resistance, return loss threshold at key frequencies, mechanical torque, visible solder fillet, and cable fit. Explanation: Use example acceptance criteria suited to system needs (for broadcast, RL better than 14–18 dB across band); document serial numbers and test data to correlate field failures with assembly records.

Troubleshooting common issues

Point: Diagnose poor RL and mating problems with a structured sequence. Evidence: Common root causes include loose nut, improper gasket, cold solder joint, bent center conductor, or debris in mating interface. Explanation: Corrective actions include re-torque, re-solder or rework fillet, clean contacts, replace mating cable, and repeat a VNA sweep; escalate to a full sweep when quick checks fail to isolate the issue.

Summary

Measured electrical specifications combined with disciplined mounting and inspection are essential to preserve 75Ω performance and ensure reliable RF links for the 4-1393682-7. Following a calibrated VNA procedure, documented torque and footprint standards, and a concise validation checklist reduces field failures and rework in broadcast and test deployments.

- Verify calibration reference plane and use SOLT/TRL on VNAs to obtain repeatable return loss and VSWR measurements for 75Ω systems.

- Control panel cutout, nut torque and gasket installation; small mechanical deviations produce measurable RF shifts and contact variability.

- Adopt a short validation checklist: contact resistance, RL threshold, solder fillet inspection and a controlled mate/unmate cycle before field deployment.

Frequently Asked Questions

How should a technician measure return loss for this jack?

Use a calibrated VNA with the reference plane at the jack face using precision adapters or a short fixture. Perform SOLT or TRL calibration, sweep the target band (e.g., 5 MHz–1 GHz for broadcast), and document RL and VSWR plots. Repeat measurements after mounting changes to isolate mechanical effects from connector electrical issues.

What torque and sealing practices prevent impedance shifts?

Hand-tighten then apply controlled torque within the connector specification range; avoid over-torquing which can deform dielectric. Use flat washer and lock washer or suitable gasket for environmental sealing. Check for panel tilt and consistent washer seating to avoid introducing asymmetric compression that shifts impedance.

When should a full VNA sweep be escalated during troubleshooting?

Perform a full VNA sweep when quick checks (continuity, visual solder inspection, torque) fail to reveal the cause of poor RL or intermittent behavior. A sweep isolates frequency-dependent anomalies and parasitic signatures indicating dielectric damage, fixture parasitics, or grounding/shielding faults that require rework or fixture redesign.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606