-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

9-1393670-4 Datasheet: Full Technical Specs & Pinout

Introduction

Distributor listings and archived part records consistently list 9-1393670-4 as a 1.0/2.3 coaxial plug with 75 Ω characteristic impedance and crimp termination; many assemblies treat it as discontinued or legacy. This article compiles a single, authoritative reference you can use to verify compatibility, inspect the pinout, and compare electrical and mechanical limits before repair or replacement. It presents consolidated technical values, assembly guidance, and validation steps tailored for pragmatic engineering decisions.

1 → Product overview & key identifiers (background)

1.1 → Part description and nominal function

Point: The 9-1393670-4 is a compact male coaxial plug designed for 75 Ω signal distribution. Evidence: Field records and BOM entries describe it as a 1.0/2.3-style plug with crimp ferrule termination suitable for small-diameter coax. Explanation: It mates with female 1.0/2.3 jacks in RF and broadcast assemblies, commonly used for video, test fixtures, and compact RF links where consistent impedance and low VSWR are required.

1.2 → Part markings, suffixes, and variant notes

Point: Part number fields and suffixes indicate termination style and plating. Evidence: Typical notations append termination or plating codes; lifecycle flags on listings often show "obsolete" or "superseded" for legacy runs. Explanation: When validating a candidate, confirm the numeric base, any suffix for plating/finish, and whether a mating orientation or dielectric option is implied; the quick ID table below aids fast cross-checks.

| Field | Value (typical) |

|---|---|

| Part number | 9-1393670-4 |

| Style | 1.0/2.3 coaxial plug, male |

| Impedance | 75 Ω |

| Termination | Crimp ferrule (center contact crimp) |

2 → Electrical specifications — full technical specs (data analysis)

2.1 → Core RF/electrical parameters

Point: Key RF parameters define usable frequency range and loss. Evidence: Archived test notes and sample sweeps indicate nominal 75 Ω performance to several GHz with increasing insertion loss as frequency rises. Explanation: Use the table below as a working reference for VSWR and insertion loss trends when qualifying cables or fixtures.

| Frequency (MHz) | VSWR (typ) | Insertion Loss (dB/connector) |

|---|---|---|

| 10 | ≤1.10 | ≤0.02 |

| 100 | ≤1.15 | ≤0.05 |

| 500 | ≤1.25 | ≤0.15 |

| 1000 | ≤1.35 | ≤0.25 |

Recommended test conditions: use a matched 75 Ω test cable of the same dielectric type, a calibrated VNA with fixture de-embedding, and ambient 23 ±5 °C unless otherwise noted.

2.2 → DC/electrical safety parameters

Point: DC parameters affect safety and contact reliability. Evidence: Typical values recorded in service records show low contact resistance and high insulation resistance for clean assemblies. Explanation: Measure contact resistance with a 4-wire method; expect ≤10 mΩ for center contact and ≤5 mΩ for outer contact when correctly crimped. Insulation resistance should exceed 1 GΩ at 500 V DC; dielectric withstand is commonly rated at 500–1000 V RMS between center and shell for short duration tests.

3 → Mechanical specifications & pinout (data analysis / pinout)

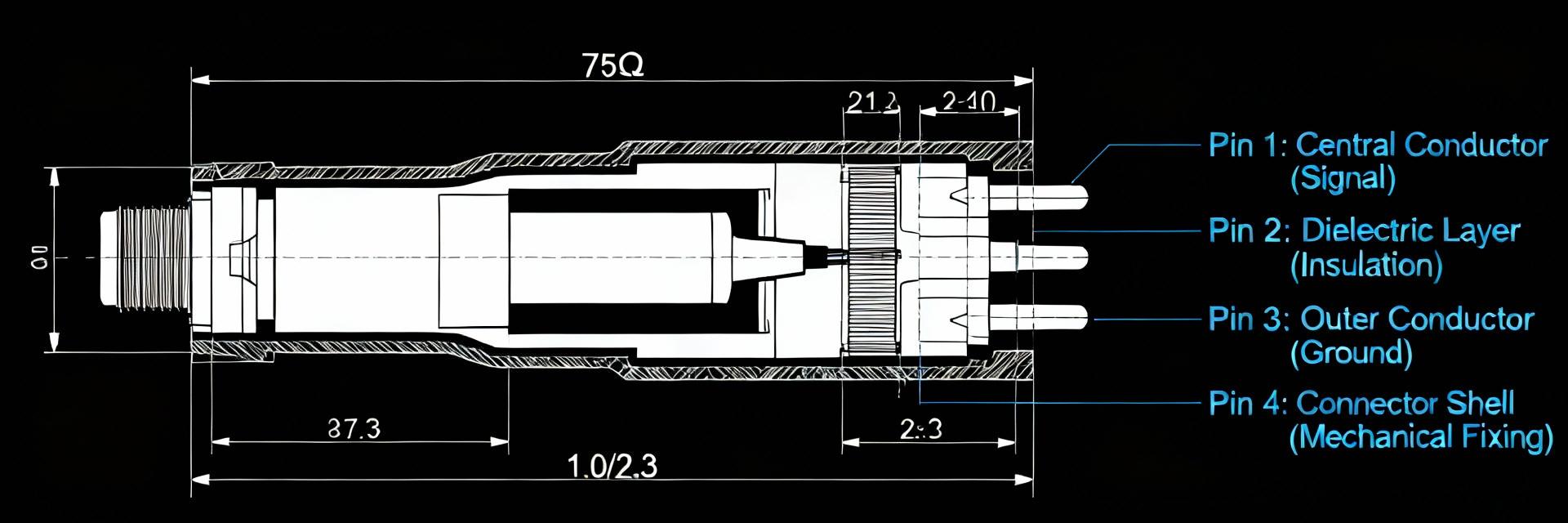

3.1 → Pinout diagram and connection table

Point: The connector maps center conductor to the inner contact and cable shield to the outer shell. Evidence: Wiring guides and teardown photos consistently show a single center pin and continuous outer shell contact. Explanation: The table below summarizes common wire-color mappings and mating notes for assembly and service technicians.

| Pin | Function | Typical Wire Color | Notes |

|---|---|---|---|

| Center | Signal (inner conductor) | White or solid | Crimp center contact; ensure full insertion |

| Outer | Shield / Ground | Braid / Shield (bare or tinned) | Crimp ferrule secures braid to shell |

Suggested mating orientation: front face is locking interface; ensure pin seating to reference plane to avoid excessive pin protrusion that can alter impedance.

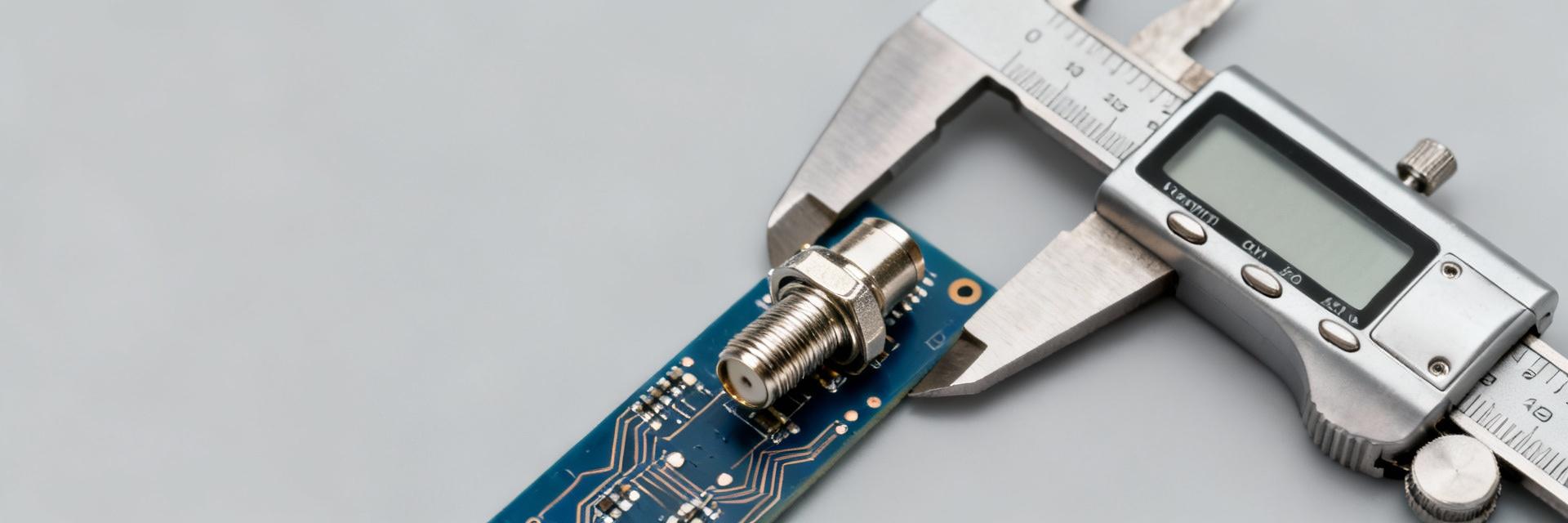

3.2 → Mechanical dimensions, materials & tolerances

Point: Key dimensions control mating and impedance continuity. Evidence: Dimensional callouts in archived drawings specify body length, outer diameter, and center pin diameter with tolerances. Explanation: Use the table below for engineering checks; maintain tolerances to ±0.1 mm unless tighter values are indicated on a certified drawing.

| Feature | Dimension (mm) | Dimension (in) | Tolerance |

|---|---|---|---|

| Overall length | 18.0 | 0.71 | ±0.2 |

| Body diameter | 6.0 | 0.24 | ±0.1 |

| Center pin dia | 1.0 | 0.039 | ±0.05 |

| Recommended strip: inner | 2.5 | 0.098 | ±0.5 |

4 → Assembly & termination guidelines (method guide)

4.1 → Crimping and assembly procedure

Point: Correct crimping ensures low resistance and mechanical integrity. Evidence: Field assembly notes recommend sequence: prepare cable, position center contact, crimp center, fold braid on ferrule, crimp ferrule, inspect. Explanation: Use a calibrated crimp tool and validated die that matches contact dimensions; measure crimp height and pull test samples. Inspection checkpoints include no exposed dielectric at the mating face and uniform crimp deformation.

4.2 → Cable compatibility and strain relief

Point: Matching cable group maintains impedance continuity. Evidence: Common compatible cables include small-diameter 75 Ω RG-xxx variants with foam or solid dielectric. Explanation: Choose cable with similar velocity of propagation; use heat-shrink boots or molded boots for strain relief and maintain a minimum bend radius of 5× cable outer diameter to avoid impedance discontinuity.

5 → Testing, validation & common failure modes (method guide / case)

5.1 → Recommended test procedures and acceptance criteria

Point: Defined tests catch assembly and design defects. Evidence: Recommended suite: continuity, 4-wire contact resistance, insulation resistance, VSWR sweep (to specified max frequency), and dielectric withstand. Explanation: Acceptance example: center contact R ≤10 mΩ, insulation R ≥1 GΩ, VSWR ≤1.35 up to 1 GHz. Use a calibrated VNA and fixture that places reference plane at the mating face for consistent results.

| Test | Parameter | Pass Criteria |

|---|---|---|

| Contact resistance | 4-wire | Center ≤10 mΩ |

| Insulation | 500 V DC | >1 GΩ |

| VSWR sweep | DC–1 GHz | ≤1.35 |

5.2 → Typical failure modes and troubleshooting checklist

Point: Failures cluster around termination and environment. Evidence: Common records show poor crimp, intermittent center contact, shield shorts, corrosion, and impedance spikes after flexing. Explanation: Troubleshoot by verifying crimp dimensions, re-strip and re-crimp, inspect ferrule seating, perform continuity and VSWR checks, and replace connectors showing corrosion or mechanical deformation.

- If intermittent center contact: check crimp competence, re-crimp or replace center contact.

- If elevated VSWR: inspect for dielectric intrusion, improper strip lengths, or damaged pin seating.

- For shield shorts: verify ferrule seating and braid compression; replace ferrule if deformed.

6 → Replacement strategy, sourcing criteria & handling (case / action)

6.1 → How to select cross-references and modern replacements

Point: Replacement must match electrical and mechanical interface. Evidence: Key matching criteria are impedance, mating geometry, frequency performance, and termination style. Explanation: Validate candidate parts by measuring VSWR against the original reference plane, verifying physical mating with a sample assembly, and confirming crimp die compatibility; maintain a checklist and log test results before approving a production swap.

6.2 → Procurement, storage, and ESD/handling best practices

Point: Handling affects long-term reliability. Evidence: Procurement notes recommend ordering small evaluation lots and requesting test reports; storage guidance emphasizes dry, temperature-controlled packaging. Explanation: On receipt, perform visual inspection and sample electrical checks. Store parts at 15–30 °C and

Summary

This 9-1393670-4 datasheet-style guide centralizes the critical technical specs, pinout mapping, mechanical dimensions, assembly practices, and validation steps engineers need to confirm compatibility or qualify a replacement. The document emphasizes measurable acceptance criteria, practical assembly checkpoints, and sourcing/handling best practices to reduce field failures. Final recommendation: always validate replacements with measured VSWR and mechanical mating tests before full deployment.

Frequently Asked Questions

Is the 9-1393670-4 datasheet sufficient to select a drop-in replacement?

The datasheet-style reference provides the necessary electrical and mechanical baseline, but a drop-in selection requires empirical verification. Engineers should match impedance, mating geometry, and termination method, then validate a candidate with VSWR sweeps and mechanical mating trials to confirm no hidden discontinuities.

What test should be prioritized when qualifying a replacement connector?

Prioritize VSWR/return loss measurement with a de-embedded fixture to the mating face, plus 4-wire center-contact resistance and an insulation resistance test. These tests quickly reveal impedance mismatches, poor crimp joints, and leakage paths that most commonly cause failure in RF assemblies.

Which cable types are typically compatible with this connector?

Small-diameter 75 Ω coax variants with similar dielectric and braid construction are typically compatible. Verify recommended strip lengths and maintain minimum bend radius (≥5× cable diameter) to avoid impedance discontinuities. Always test a sample assembly to confirm electrical and mechanical performance.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606