-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1274220-1 datasheet: Complete C-Type RF specs guide

The 1274220-1 datasheet is the starting point for engineers evaluating C‑Type coaxial RF contacts. This concise guide distills the measurable specs you need — impedance, frequency behavior, mechanical durability, and test acceptance criteria — so teams can interpret tables, map values into lab procedures, and speed procurement decisions.

Use this one‑page roadmap to compare C‑Type RF specs across part families and validate parts in lab and field environments. The intent is practical: translate datasheet rows into go/no‑go checks, test set ups, and installation notes that preserve RF performance under real operating conditions.

1 — Quick overview: what the 1274220-1 datasheet shows and C‑Type basics

1.1 — Physical form & intended use

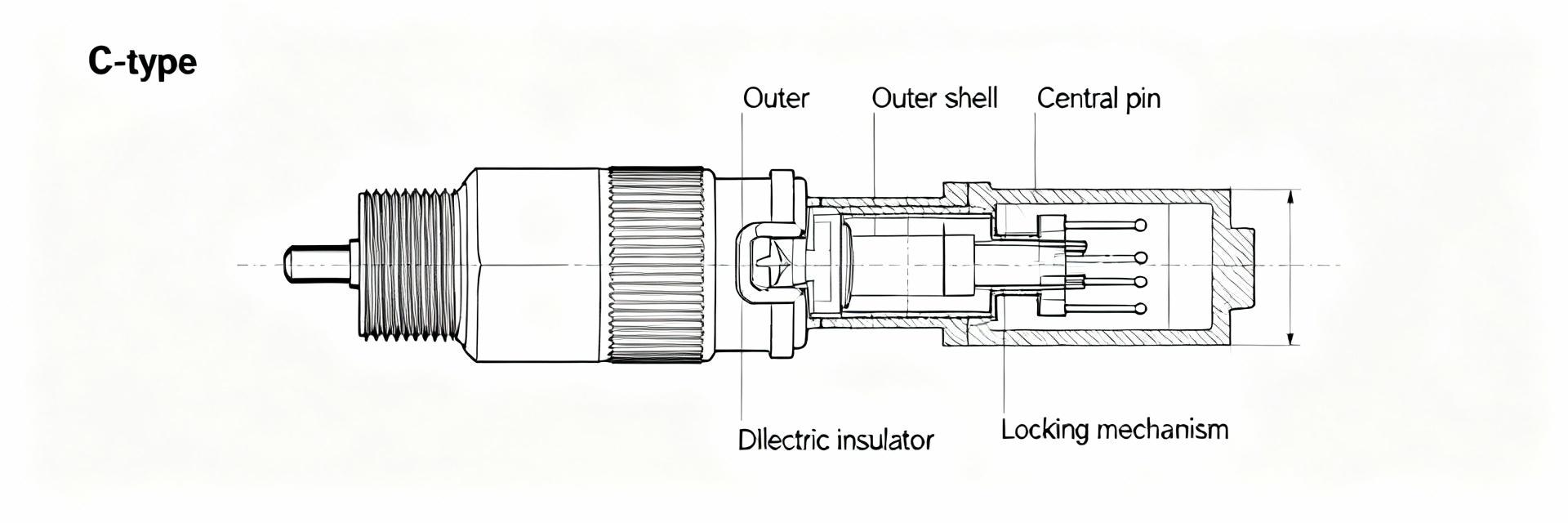

Point: C‑Type is a full‑size coaxial contact intended as a socket/jack in straight orientation with a solder termination. Evidence: the datasheet part description lists a coaxial contact designed for panel or cable assembly with a solder cup termination. Explanation: this form factor prioritizes mechanical robustness and repeatable mating for test ports and mid‑size outdoor assemblies.

1.2 — How C‑Type differs from other RF connectors

Point: C‑Type trades compactness for robustness. Evidence: compared to bayonet or miniature types, C‑Type uses a larger coupling interface and heavier shell, favoring weatherproofing and easier torque control. Explanation: choose C‑Type when mechanical durability and moderate GHz performance outweigh the need for extreme miniaturization.

2 — Electrical performance at a glance (C‑Type RF specs)

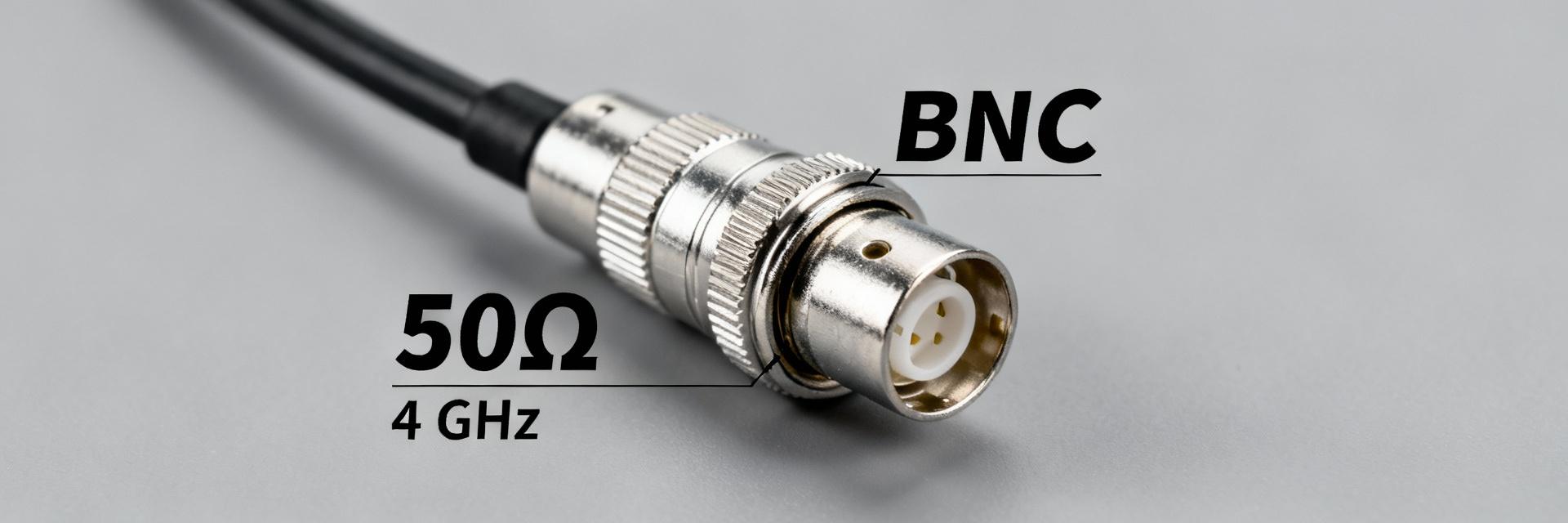

2.1 — Impedance, frequency range, and return loss

Point: Typical C‑Type RF specs show a nominal 50 Ω impedance and a frequency span suitable for several GHz bands. Evidence: datasheet electrical tables specify rated impedance and recommended max frequency; return loss/VSWR rows show dB or ratio limits by band. Explanation: read the impedance column, then compare VSWR or return loss entries to your system budget; flag any band where return loss degrades.

2.2 — Insertion loss, power handling, and RF power limits

Point: Insertion loss is usually small but rises with frequency; power handling is thermal‑limited. Evidence: datasheet typically lists insertion loss per frequency or a maximum dB value and a DC or RF power/voltage rating with temperature notes. Explanation: use those numbers to set acceptance thresholds and derate continuous power for elevated ambient temps or pulse duty cycles.

3 — Mechanical & materials summary (interpreting mechanical data)

3.1 — Contact type, termination method, and mating durability

Point: Contact geometry and termination determine reliability. Evidence: the datasheet describes center contact type (pin or socket), solder termination style, and published mating cycles. Explanation: extract mating cycle counts and acceptance criteria; for test ports prefer higher cycle ratings and verify contact retention torque during qualification.

3.2 — Materials, plating, and environmental ratings

Point: Shell and center conductor materials affect conductivity and corrosion resistance. Evidence: tables list base metals and plating (e.g., brass with gold flash or nickel underplate) plus temperature and environmental notes. Explanation: choose plating for low contact resistance and corrosion profiles matching outdoor or marine environments; confirm any sealing or IP claims in the environmental spec rows.

4 — Interpreting datasheet drawings, dimensions, and tables

4.1 — Reading mechanical drawings and footprint guidance

Point: Mechanical drawings contain critical CAD dimensions. Evidence: views show centerline, panel cutout, mounting holes, and tolerances. Explanation: copy centerline-to-cutout distances and hole sizes directly into CAD, check tolerances, and confirm clearance for coupling action before panel or PCB orders.

4.2 — Key tables to extract (electrical, mechanical, environmental)

Point: Certain tables belong in design docs verbatim. Evidence: electrical characteristics, mechanical specifications, materials/finish, and ordering information are the essential extracts. Explanation: build a snapshot table with units and test conditions noted (temperature, reference plane) so test engineers and procurement have consistent reference values.

5 — Test procedures to validate C‑Type RF specs in the lab

5.1 — Required RF measurements and test setups

Point: Validate RF behavior with calibrated VNA and time‑domain tools. Evidence: standard bench tests include VSWR/return loss, insertion loss, TDR for discontinuities, and insulation/continuity checks. Explanation: use SOLT or TRL calibration to set reference planes at the mating face, use appropriate test fixtures, and condition connectors by cycling before measurement.

5.2 — Common pitfalls and acceptance criteria

Point: Measurement errors often arise from adapter mismatch or torque variance. Evidence: common issues include cable loss, improper torque, and uncalibrated fixtures. Explanation: set pass/fail rules such as VSWR below datasheet max plus margin and insertion loss within listed tolerances across critical bands; log ambient temp for power tests and repeat after specified mating cycles.

6 — Selection checklist, compatibility notes, and example deployment scenarios

6.1 — Quick selection checklist for procurement and engineering

Point: A concise procurement checklist avoids costly mismatches. Evidence: verify impedance, rated frequency, termination method, mating cycles, environmental rating, and mechanical footprint. Explanation: confirm compatibility with mating connectors and cables, and include required test fixture types and torque specs in purchase orders so parts arrive ready for qualification.

6.2 — Example deployment scenarios & compatibility considerations

Point: Different applications prioritize different specs. Evidence: a lab front‑panel test port prioritizes mating cycles and low VSWR; an outdoor antenna feed prioritizes weatherproofing and corrosion resistance. Explanation: choose adapters and sealing practices accordingly and follow torque and assembly best practices to preserve repeatable RF performance in the field.

Summary

Use the 1274220-1 datasheet as the authoritative source for core values — impedance, frequency bounds, VSWR, termination style, and mechanical limits. This guide translates those rows into lab tests, procurement checks, and installation guidance so engineers can quickly verify compatibility and performance against system requirements.

- Extract and record core electrical values (impedance, VSWR, insertion loss) from the datasheet into a single design‑validation table to streamline lab acceptance and procurement checks.

- Confirm mechanical footprint and mating cycles: copy centerline, panel cutout, and torque specs into CAD and procurement specs to avoid fit and durability failures.

- Define lab pass/fail rules: use calibrated VNA measurements with SOLT/TRL, derate power by temperature, and require VSWR and IL within the datasheet plus a safety margin.

Frequently Asked Questions

What is the nominal impedance for C‑Type RF specs and where is it in the datasheet?

The nominal impedance is typically 50 Ω and appears in the electrical characteristics table. Use that value to match cable and instrument systems; any mismatch here is the primary source of return loss. For precise impedance and recommended maximum frequency, refer to the datasheet electrical rows for the authoritative numbers.

How should I validate VSWR and insertion loss against datasheet values?

Validate with a calibrated VNA using SOLT or TRL, placing the reference plane at the mating face. Measure return loss/VSWR and insertion loss across target bands, and compare to datasheet limits. Set pass thresholds as datasheet max plus a design margin to account for fixture and cable uncertainties.

What mechanical checks ensure field reliability for C‑Type contacts?

Verify mating durability (published cycles), contact retention, and plating corrosion resistance. Inspect mechanical drawings for panel cutout and mounting tolerances, apply specified torque values during assembly, and follow any sealing or environmental conditioning in the datasheet for outdoor deployments.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606