-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

1488886-5 Coaxial Connector: Complete Datasheet & Specs

Accurate connector specifications reduce RF failures: impedance mismatch or poor solder joints are common causes of return-loss spikes and intermittent connections. This guide walks engineers through the full datasheet-level specs for the 1488886-5 coaxial connector and shows how to accelerate selection, PCB layout, soldering, validation, and procurement decisions.

Readers will learn electrical and mechanical parameters, footprint and soldering guidance, reliability and compliance checkpoints, plus a procurement checklist to request the correct drawings, test reports, and samples before production.

1 — Part Overview & Key Identifiers (background introduction)

What the part number means and typical applications

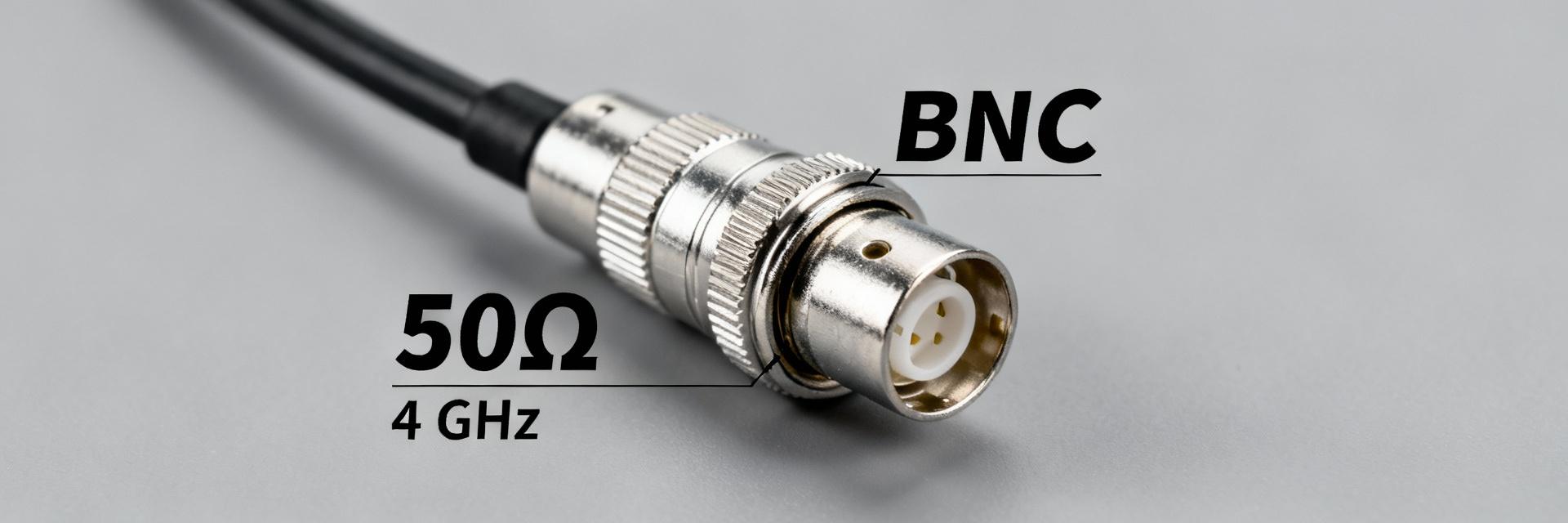

Point: The numeric identifier indicates a board-mounted RF jack variant used on PCB assemblies. Evidence: Datasheet figure callouts define form factor and mounting notes. Explanation: Expect a compact PCB-coax jack intended for board-level RF paths in wireless modules, instrumentation, or broadcast equipment where 50 Ω matching and low-profile mounting matter.

Key identifiers to confirm before spec use

Point: Confirm variant details before design release. Evidence: Datasheet sections list orientation, mounting type, mating gender, and revision. Explanation: Check pin count, straight vs. right-angle, through-hole vs. surface-mount, and drawing revision; use a quick checklist: part suffix, orientation, mounting method, and drawing number to ensure the correct variant.

2 — Electrical Specifications & Performance (data analysis)

Core electrical specs to extract from the datasheet

Point: Extract impedance, frequency range, VSWR, insertion loss, contact and insulation resistance, and rated voltage/current. Evidence: Typical datasheet entries specify 50 Ω impedance, GHz-range frequency bounds, and return-loss limits. Explanation: Note test conditions—"measured at X GHz, Y dB max insertion loss"—and translate values into design margins for RF chain budgets.

Measurement methods and real-world performance tips

Point: Measurement setup affects reported numbers. Evidence: Datasheets often cite VNA test fixtures and reference planes. Explanation: Use network analyzer with de-embedded fixtures, prioritize impedance match and VSWR for high-frequency lines, and allow margins (e.g., reserve 0.5–1.0 dB headroom) to accommodate assembly variance and temperature shifts.

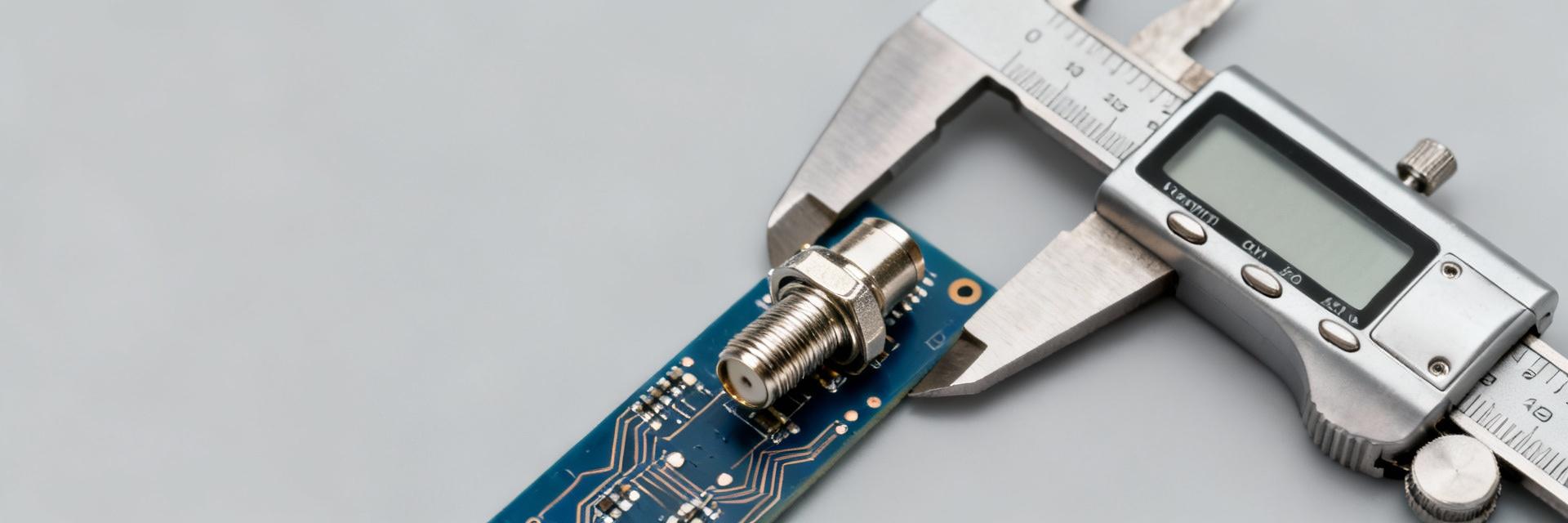

3 — Mechanical Dimensions & Footprint (data & method)

Drawing walkthrough: critical dimensions and tolerances

Point: Mechanical drawing defines critical PCB and mating clearances. Evidence: Datasheet drawings list PCB hole sizes, pad dimensions, body envelope, and heights. Explanation: Extract drill sizes, pad coordinates, mounting hole diameters, and tolerance stacks; ensure clearance for mating connectors and proper mating depth to avoid interference with housings or shields.

PCB footprint recommendations and placement rules

Point: Footprint choices affect solder reliability and mechanical stability. Evidence: Datasheet often recommends pad shapes and keepouts. Explanation: Use plated through-hole annular rings sized per drill, provide solder fillet areas, thermal reliefs for wave solder, mask openings aligned to pads, and add stitching vias or mechanical anchors near load points to reduce stress during mating cycles.

4 — Mounting, Soldering & Assembly Guidelines (method guide)

Soldering methods and reflow/wave profile guidance

Point: Soldering profile impacts plating and insulation. Evidence: If present, the datasheet specifies peak reflow temp and allowed methods. Explanation: When datasheet is silent, use conservative profiles: peak 240–250 °C (464–482 °F) for lead-free reflow with controlled preheat and ramp rates; avoid prolonged high-temperature exposure, inspect fillets, and check for body deformation after assembly.

Mechanical assembly and handling best practices

Point: Handling affects contact life and ESD-sensitive surfaces. Evidence: Datasheet durability and mating cycle figures indicate expected life. Explanation: Adhere to specified insertion/removal forces and mating cycles; use assembly fixtures for consistent placement, torque screws per spec if provided, and use ESD precautions to avoid contact contamination or plating damage prior to final test.

5 — Environmental, Reliability & Compliance (data analysis + method)

Thermal, vibration, and durability specs to check

Point: Environmental tests predict field reliability. Evidence: Datasheet sections list operating temperatures, vibration, shock, and mating cycle counts. Explanation: Verify operating/storage temperature ranges, vibration and shock profiles, and specified mating cycles; design with margins—select parts rated beyond expected field extremes to meet target reliability goals.

Regulatory, material compliance and traceability

Point: Compliance and material finish affect corrosion and procurement acceptance. Evidence: Datasheet compliance notes often include RoHS/REACH and plating finish. Explanation: Verify RoHS/REACH statements, plating material (gold/nickel), and request traceability lot codes and certificates of conformity for high-reliability programs; request test reports or PPAP-level documentation when required.

6 — Procurement, Alternatives & Datasheet Checklist (action & case)

Buying checklist and what to confirm with suppliers

Point: Procurement must lock details to avoid variants. Evidence: Datasheet and packing notes list revision, packaging, and MOQ. Explanation: Confirm full part number and revision, packaging type, MOQ, lead time, country of origin, and sample/test-report availability; when datasheet is incomplete, request mechanical CAD and raw test data before placement of large orders.

Compatible alternatives and substitution criteria

Point: Substitutions require documented equivalence. Evidence: Alternative part tables or cross-reference notes guide substitutions. Explanation: Prioritize form-fit-function, electrical spec matches (impedance, frequency rating, VSWR), mechanical fit, and materials/compliance; document interchange decisions and validate substitutes with electrical and mechanical tests before production.

Summary

The goal is a disciplined extraction of the 1488886-5 datasheet so engineers can select, lay out, assemble, and procure with confidence. The three critical checks are: electrical spec alignment (impedance/VSWR), accurate footprint and PCB rules, and full reliability/compliance documentation to support production and field performance.

- Verify electrical specs and test conditions to ensure 50 Ω match and acceptable VSWR for the intended frequency band; prioritize impedance and insertion-loss margins in system budget.

- Confirm mechanical drawing dimensions and footprint tolerances; implement recommended pad shapes, drill sizes, and mechanical anchors to secure the PCB jack.

- Request compliance and traceability documentation, mating-cycle data, and sample test reports from suppliers when qualifying parts for production to reduce risk.

Common Questions

How do I verify coaxial connector electrical specifications on a PCB?

Use a calibrated vector network analyzer with fixture de-embedding to measure return loss and insertion loss at design frequencies. Compare measured VSWR and insertion loss to datasheet test condition values, apply margins for assembly variance, and validate across expected temperature ranges to confirm real-world performance.

What footprint checks should be performed before ordering PCB stencils for a coaxial connector?

Review datasheet mechanical drawings for drill sizes, pad dimensions, and keepout zones. Verify annular ring sizes, solder mask openings, and ensure thermal reliefs for through-holes. Cross-check footprint in the CAD library against the drawing revision to prevent misplacement or interference with housings.

Which reliability documents should procurement request when qualifying a coaxial connector?

Request RoHS/REACH declarations, material plating details, lot traceability, mating-cycle test reports, vibration/shock test results, and certificates of conformity. For high-reliability programs, ask for detailed test reports or PPAP-style documentation and sample units for incoming electrical and mechanical testing.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

- 1757255 MSTBA 5.08mm PCB: Step-by-Step Install & Solder

-

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606

EXB-V4V120JVPanasonic Electronic ComponentsRES ARRAY 2 RES 12 OHM 0606 -

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606

EXB-V4V473JVPanasonic Electronic ComponentsRES ARRAY 2 RES 47K OHM 0606 -

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606

EXB-V4V823JVPanasonic Electronic ComponentsRES ARRAY 2 RES 82K OHM 0606 -

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606

EXB-V4V151JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150 OHM 0606 -

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606

EXB-V4V181JVPanasonic Electronic ComponentsRES ARRAY 2 RES 180 OHM 0606 -

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606

EXB-V4V331JVPanasonic Electronic ComponentsRES ARRAY 2 RES 330 OHM 0606 -

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606

EXB-V4V152JVPanasonic Electronic ComponentsRES ARRAY 2 RES 1.5K OHM 0606 -

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606

EXB-V4V563JVPanasonic Electronic ComponentsRES ARRAY 2 RES 56K OHM 0606 -

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606

EXB-V4V104JVPanasonic Electronic ComponentsRES ARRAY 2 RES 100K OHM 0606 -

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606

EXB-V4V154JVPanasonic Electronic ComponentsRES ARRAY 2 RES 150K OHM 0606